Rockwell Automation stands as a beacon of innovation in the realm of industrial automation and digital transformation. Founded in 1903, the company has evolved from its humble beginnings into a global leader, providing cutting-edge solutions that empower manufacturers to enhance productivity, efficiency, and sustainability. With a commitment to advancing technology, Rockwell Automation integrates hardware, software, and services to create a seamless ecosystem that supports the modern manufacturing landscape.

Their extensive portfolio includes everything from programmable logic controllers (PLCs) to advanced analytics, all designed to meet the diverse needs of industries ranging from automotive to food and beverage. As the manufacturing sector faces increasing pressure to adapt to rapid technological changes, Rockwell Automation has positioned itself at the forefront of this evolution. The company recognizes that the future of manufacturing lies in the convergence of operational technology (OT) and information technology (IT).

By leveraging the Internet of Things (IoT), artificial intelligence (AI), and machine learning, Rockwell Automation is not only enhancing traditional manufacturing processes but also paving the way for smart factories.

Key Takeaways

- Rockwell Automation is a leading provider of industrial automation and information technology.

- Industrial robotics is transforming manufacturing processes by increasing efficiency and precision.

- Factory automation is optimizing operations by integrating machinery and processes for seamless production.

- Process improvement is crucial for enhancing efficiency and quality in manufacturing.

- Energy efficiency is a key focus for sustainability in manufacturing, and Rockwell Automation offers solutions for this.

Industrial Robotics: Revolutionizing Manufacturing

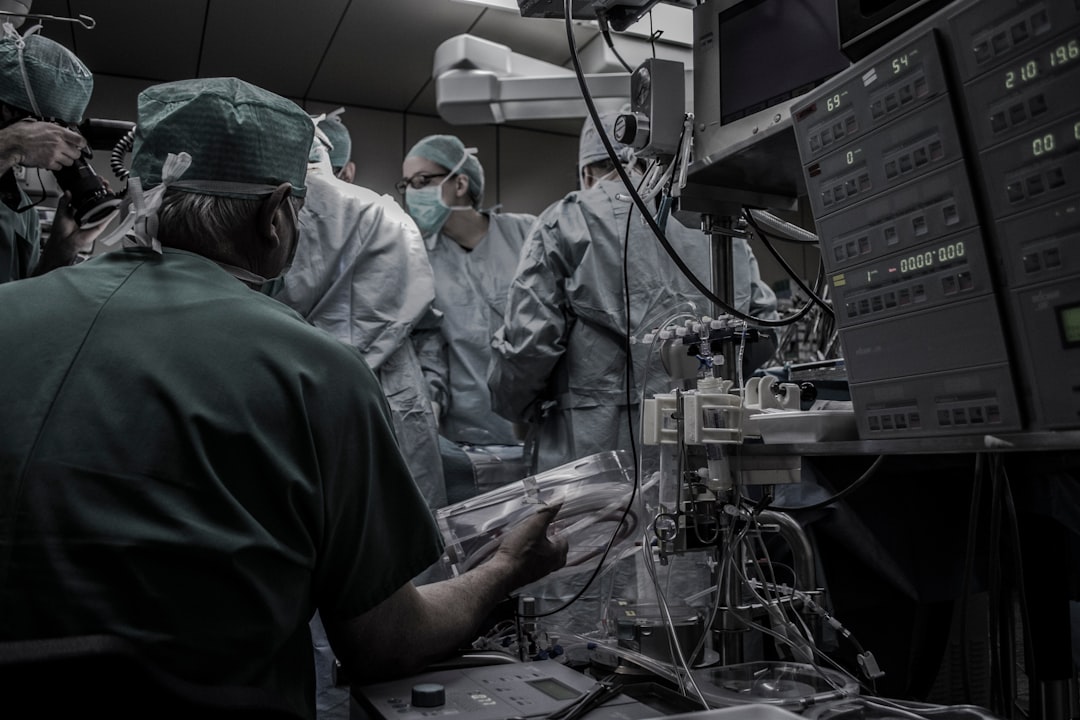

Enhancing Human-Machine Collaboration

Rockwell Automation’s robotics solutions are designed to foster collaboration between humans and machines, creating a harmonious work environment where both can thrive. By working together, humans and machines can optimize production processes, improve product quality, and increase overall efficiency.

Flexibility and Adaptability

One of the key benefits of Rockwell Automation’s approach to industrial robotics is its focus on flexibility. Unlike traditional manufacturing setups that relied on rigid automation systems, Rockwell Automation’s solutions can be easily reprogrammed for different tasks or products. This adaptability reduces downtime, allows for greater customization in production processes, and enables manufacturers to respond quickly to changing market demands.

Staying Competitive in a Dynamic Market

As industries strive for agility in response to market demands, Rockwell Automation’s robotics solutions provide the necessary tools to stay competitive. By leveraging the power of industrial robotics, manufacturers can improve product quality, reduce costs, and increase productivity, ultimately gaining a competitive edge in their respective markets.

Factory Automation: Streamlining Operations

Factory automation is another critical area where Rockwell Automation excels, offering solutions that streamline operations and enhance overall productivity. By automating repetitive tasks, manufacturers can free up human resources for more strategic roles, ultimately leading to improved job satisfaction and reduced error rates. Rockwell’s factory automation solutions encompass a wide range of technologies, including advanced control systems, sensors, and data analytics tools that work together to optimize production processes.

The integration of smart technologies into factory automation allows for real-time monitoring and control of operations. With Rockwell Automation’s systems, manufacturers can gain insights into their production lines, identifying bottlenecks and inefficiencies that may hinder performance. This data-driven approach enables proactive decision-making, allowing companies to adjust their operations dynamically based on real-time feedback.

As a result, manufacturers can achieve higher throughput while maintaining quality standards, ultimately driving profitability.

Process Improvement: Enhancing Efficiency and Quality

| Metrics | Current | Target |

|---|---|---|

| Defect Rate | 5% | 3% |

| Lead Time | 10 days | 7 days |

| Customer Satisfaction | 80% | 90% |

| Process Cycle Efficiency | 70% | 85% |

In an era where efficiency and quality are paramount, Rockwell Automation’s commitment to process improvement is evident in its innovative solutions. The company employs a holistic approach that encompasses not only technology but also best practices in operational management. By leveraging data analytics and machine learning algorithms, Rockwell Automation helps manufacturers identify areas for improvement within their processes, leading to enhanced efficiency and product quality.

One of the key components of Rockwell’s process improvement strategy is its emphasis on continuous improvement methodologies such as Lean and Six Sigma. These frameworks enable organizations to systematically analyze their processes, eliminate waste, and optimize workflows. By integrating these methodologies with advanced automation technologies, Rockwell Automation empowers manufacturers to create a culture of excellence where every employee is engaged in the pursuit of operational excellence.

This not only leads to better products but also fosters a sense of ownership among employees.

Energy Efficiency: Sustainability in Manufacturing

As global awareness of environmental issues continues to rise, energy efficiency has become a critical focus for manufacturers seeking sustainable practices. Rockwell Automation recognizes the importance of reducing energy consumption not only for cost savings but also for minimizing environmental impact. The company’s energy efficiency solutions are designed to help manufacturers optimize their energy usage while maintaining productivity levels.

Through advanced monitoring systems and analytics tools, Rockwell Automation enables manufacturers to track their energy consumption in real-time. This visibility allows organizations to identify inefficiencies and implement targeted strategies for improvement. For instance, by analyzing energy usage patterns, manufacturers can schedule operations during off-peak hours or invest in energy-efficient equipment that reduces overall consumption.

By prioritizing sustainability through energy efficiency initiatives, Rockwell Automation helps manufacturers align their operations with global sustainability goals while enhancing their bottom line.

Rockwell Automation’s Solutions for Industrial Robotics

Seamless Integration into Existing Manufacturing Environments

Their portfolio includes robotic arms, vision systems, and software platforms that facilitate seamless integration into existing manufacturing environments. One notable offering is the Allen-Bradley® robotic product line, which provides a range of options suitable for various applications—from assembly and packaging to material handling.

Interoperability for Cohesive Production Lines

The company’s focus on interoperability ensures that its robotic solutions can easily communicate with other automation systems within a facility. This capability is crucial for creating cohesive production lines where robots can work alongside traditional machinery without disruption. Additionally, Rockwell Automation’s software solutions enable users to program and monitor robotic systems efficiently, reducing the learning curve associated with new technologies.

Empowering Manufacturers through Training and Support

By providing robust training resources and support services, Rockwell Automation empowers manufacturers to harness the full potential of industrial robotics.

Rockwell Automation’s Solutions for Factory Automation

Rockwell Automation’s factory automation solutions are designed to create intelligent manufacturing environments that respond dynamically to changing conditions. The company’s FactoryTalk® software suite serves as a central hub for data collection and analysis, enabling manufacturers to gain insights into their operations in real-time. This visibility allows organizations to make informed decisions that drive efficiency and productivity.

In addition to software solutions, Rockwell Automation offers a range of hardware components such as controllers, sensors, and drives that work together seamlessly within an automated factory setting. These components are engineered for reliability and performance, ensuring that production lines operate smoothly even under demanding conditions. Furthermore, Rockwell’s commitment to cybersecurity ensures that factory automation systems remain secure from potential threats, safeguarding sensitive data and maintaining operational integrity.

Rockwell Automation’s Solutions for Process Improvement and Energy Efficiency

Rockwell Automation’s dedication to process improvement extends beyond traditional manufacturing practices; it encompasses energy efficiency initiatives as well. The company’s integrated approach combines advanced analytics with energy management tools to help manufacturers optimize their processes while minimizing energy consumption. By leveraging data-driven insights, organizations can identify inefficiencies in their workflows and implement targeted improvements that enhance both productivity and sustainability.

One innovative solution offered by Rockwell Automation is its Energy Management System (EMS), which provides real-time monitoring of energy usage across facilities. This system enables manufacturers to track their consumption patterns and identify opportunities for reduction without compromising output quality. By integrating energy efficiency into process improvement strategies, Rockwell Automation empowers manufacturers to achieve their operational goals while contributing positively to environmental sustainability.

In conclusion, Rockwell Automation stands as a leader in the industrial automation landscape, offering a diverse range of solutions that address the evolving needs of modern manufacturing. From industrial robotics to factory automation and process improvement initiatives focused on energy efficiency, the company is committed to driving innovation and excellence across industries. As technology continues to advance at an unprecedented pace, Rockwell Automation remains dedicated to helping manufacturers navigate this transformation successfully while achieving their operational objectives sustainably.

For those interested in exploring how advanced technologies like those offered by Rockwell Automation are shaping the future of industries, the article “Metaverse and Industries: Entertainment and Media in the Metaverse” provides insightful perspectives. This piece delves into the integration of digital and physical realities, highlighting the transformative impact on various sectors, including industrial automation and robotics. To read more about how these technologies are influencing entertainment and media, and potentially overlapping with industrial applications like those from Rockwell Automation, you can visit the article here.

FAQs

What is Rockwell Automation?

Rockwell Automation is a global provider of industrial automation and information products. They offer a wide range of solutions for factory automation, industrial robotics, process improvement, and energy efficiency.

What types of solutions does Rockwell Automation offer?

Rockwell Automation offers a variety of solutions including automation control systems, industrial robots, factory automation equipment, process improvement technologies, and energy efficiency solutions.

What industries does Rockwell Automation serve?

Rockwell Automation serves a wide range of industries including automotive, food and beverage, oil and gas, pharmaceutical, and many others. They provide solutions for both discrete and process manufacturing industries.

How does Rockwell Automation help with process improvement?

Rockwell Automation offers a range of technologies and solutions to help improve manufacturing processes, including advanced control systems, data analytics, and predictive maintenance tools.

What are the benefits of using Rockwell Automation’s solutions?

Using Rockwell Automation’s solutions can help improve productivity, reduce downtime, increase efficiency, and optimize energy usage in manufacturing facilities. Their technologies can also help companies meet regulatory requirements and improve overall operational performance.

Leave a Reply