Fanuc Robotics stands as a titan in the realm of industrial automation, renowned for its cutting-edge technology and innovative solutions. Established in 1956, Fanuc has evolved from a small company into a global leader in robotics and factory automation. With a commitment to enhancing productivity and efficiency, Fanuc has developed a diverse range of robotic systems that cater to various industries, including automotive, electronics, food and beverage, and pharmaceuticals.

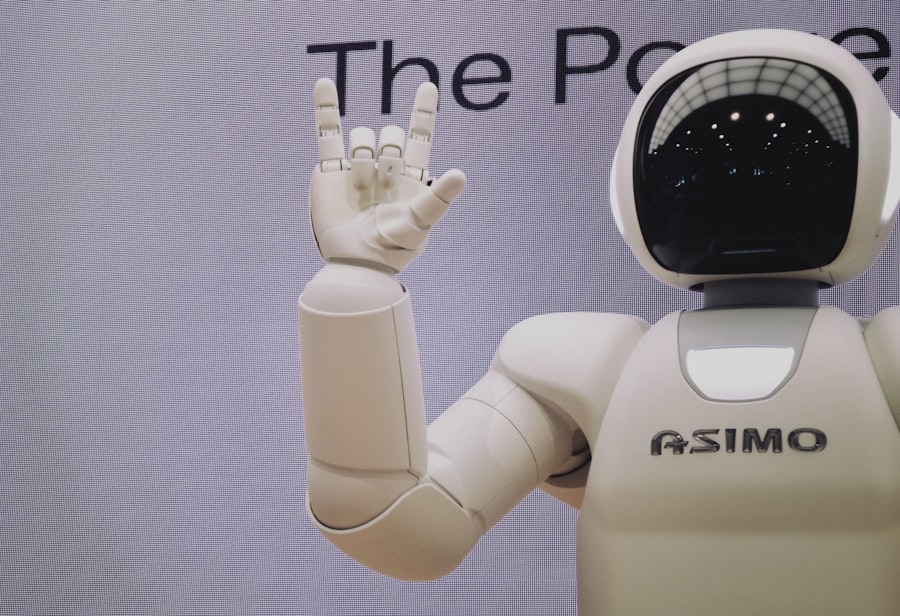

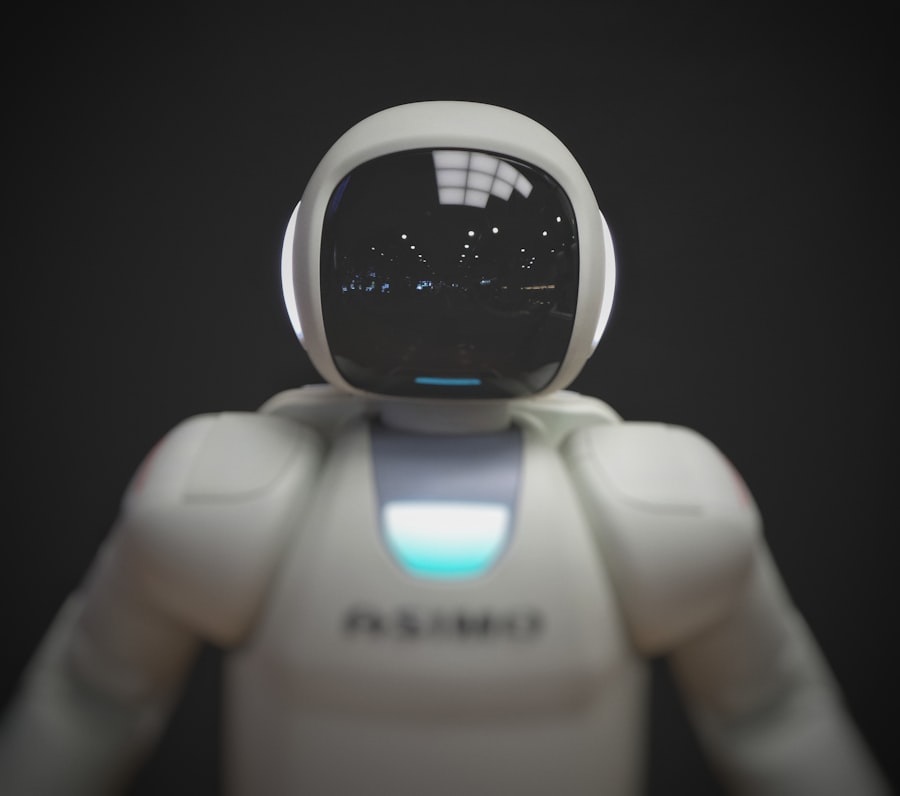

The core philosophy of Fanuc Robotics revolves around the idea of creating intelligent machines that can work alongside humans to optimize production lines.

0 revolution.

This integration of smart technology not only enhances operational efficiency but also allows for real-time data analysis and decision-making, paving the way for more agile and responsive manufacturing environments.

Key Takeaways

- Fanuc Robotics is a leading provider of automation solutions for various industries, including welding, painting, and material handling.

- Fanuc Robotics offers welding automation solutions that improve productivity, quality, and safety in the welding process.

- Painting automation solutions by Fanuc Robotics provide consistent and high-quality finishes while reducing waste and improving efficiency.

- Material handling automation solutions by Fanuc Robotics optimize production processes and increase overall efficiency in material handling tasks.

- Using Fanuc Robotics for industry automation offers benefits such as increased productivity, improved quality, and enhanced worker safety.

Welding Automation Solutions by Fanuc Robotics

Welding is a critical process in many manufacturing sectors, and Fanuc Robotics has developed specialized solutions to streamline this operation. Their welding robots are designed to perform various types of welding, including arc welding, spot welding, and laser welding, with precision and speed that far surpasses human capabilities. These robots are equipped with advanced sensors and software that enable them to adapt to different materials and welding techniques, ensuring high-quality welds every time.

One of the standout features of Fanuc’s welding automation solutions is their ability to reduce downtime and increase throughput. By automating the welding process, manufacturers can achieve consistent results while minimizing the risk of human error. Additionally, Fanuc’s robots can operate in challenging environments where human workers may be at risk, such as high-temperature or hazardous areas.

This not only enhances safety but also allows for continuous operation, significantly boosting productivity.

Painting Automation Solutions by Fanuc Robotics

In the realm of painting and coating applications, Fanuc Robotics offers state-of-the-art solutions that enhance both quality and efficiency. Their pAInting robots are engineered to deliver precise and uniform coatings on a variety of surfaces, from automotive parts to industrial machinery. These robots utilize advanced spray technology that optimizes paint usage while minimizing waste, making them an environmentally friendly choice for manufacturers.

Fanuc’s painting automation solutions also incorporate sophisticated software that allows for easy programming and customization. Users can quickly adjust parameters such as spray patterns, speed, and paint flow to accommodate different projects without extensive downtime. This flexibility is particularly beneficial in industries where product lines frequently change or where customization is key.

Furthermore, the integration of vision systems enables these robots to detect surface imperfections and adjust their application techniques accordingly, ensuring a flawless finish every time.

Material Handling Automation Solutions by Fanuc Robotics

| Metrics | Value |

|---|---|

| Throughput | Up to 2000 units per hour |

| Accuracy | ±0.1mm |

| Flexibility | Can handle multiple SKUs |

| Footprint | Compact design for space optimization |

| Integration | Seamless integration with existing systems |

Material handling is another area where Fanuc Robotics excels, providing solutions that streamline the movement of goods within manufacturing facilities. Their material handling robots are designed to automate tasks such as loading and unloading, palletizing, and sorting, which are often labor-intensive and time-consuming when performed manually. By implementing these robotic systems, companies can significantly reduce labor costs while improving efficiency and accuracy.

Fanuc’s material handling solutions are characterized by their versatility and adaptability. The robots can be easily integrated into existing workflows and can handle a wide range of products, from small components to large pallets. Additionally, their advanced navigation systems allow them to operate safely alongside human workers, making them an ideal choice for collaborative environments.

The ability to collect and analyze data during operations also provides valuable insights into workflow optimization, further enhancing productivity.

Benefits of Using Fanuc Robotics for Industry Automation

The advantages of incorporating Fanuc Robotics into industrial processes are manifold. First and foremost is the significant increase in productivity that these automated systems provide. By taking over repetitive tasks that would otherwise require human labor, companies can allocate their workforce to more strategic roles that require creativity and problem-solving skills.

This shift not only enhances overall efficiency but also contributes to employee satisfaction by reducing monotonous work. Moreover, Fanuc Robotics enhances product quality through precision and consistency. Automated systems are less prone to errors compared to human workers, leading to fewer defects and higher-quality outputs.

This reliability is crucial in industries where quality control is paramount. Additionally, the integration of robotics can lead to reduced operational costs over time due to lower labor expenses and decreased material waste. As companies strive for greater sustainability, these benefits align perfectly with modern manufacturing goals.

Case Studies of Successful Implementations of Fanuc Robotics

Numerous companies across various sectors have successfully implemented Fanuc Robotics solutions, showcasing the transformative impact of automation on their operations. For instance, a leading automotive manufacturer adopted Fanuc’s welding robots to enhance its production line efficiency. By automating the welding process, the company was able to reduce cycle times by 30% while maintaining high-quality standards.

The integration of these robots not only improved throughput but also allowed for greater flexibility in production scheduling. Another compelling case study involves a food processing company that implemented Fanuc’s material handling robots to streamline its packaging operations. The robots were tasked with loading products onto pallets for shipment, a process that was previously labor-intensive and prone to errors.

After integrating the robotic system, the company reported a 40% increase in packing speed and a significant reduction in product damage during handling. This success story highlights how Fanuc Robotics can drive efficiency across diverse industries while addressing specific operational challenges.

Future Trends in Industry Automation with Fanuc Robotics

As we look toward the future of industry automation, several trends are emerging that will shape the landscape in which Fanuc Robotics operates. One significant trend is the increasing adoption of collaborative robots (cobots) that work alongside human operators. These cobots are designed with safety features that allow them to operate in close proximity to people without compromising safety.

This trend reflects a growing recognition of the value of human-robot collaboration in enhancing productivity while maintaining a safe working environment. Another trend is the integration of artificial intelligence (AI) into robotic systems. As AI technology continues to advance, we can expect Fanuc Robotics to incorporate more intelligent algorithms that enable robots to learn from their environments and improve their performance over time.

This capability will allow for greater adaptability in manufacturing processes, enabling robots to handle more complex tasks with minimal human intervention. Additionally, the rise of IoT will facilitate real-time data sharing between machines, leading to smarter factories that can optimize operations dynamically.

Conclusion and Recommendations for Implementing Fanuc Robotics in Industry

In conclusion, Fanuc Robotics offers a comprehensive suite of automation solutions that can significantly enhance productivity, quality, and safety across various industries. As companies navigate the challenges of modern manufacturing, integrating these advanced robotic systems can provide a competitive edge in an increasingly automated world. To successfully implement Fanuc Robotics in your operations, it is essential to conduct a thorough assessment of your specific needs and workflows.

Start by identifying areas where automation can deliver the most significant impact—whether through welding, painting, or material handling solutions—and consider pilot projects to test the effectiveness of these systems before full-scale implementation. Additionally, investing in training for your workforce will ensure that employees are equipped to work alongside these advanced technologies effectively. By embracing the capabilities offered by Fanuc Robotics, businesses can position themselves for success in an era defined by innovation and efficiency.

For those interested in the intersection of advanced robotics and business strategy, particularly in the context of companies like Fanuc Robotics, which specializes in industrial robotics and automation solutions, the article “Challenges and Opportunities: Business and Economic Perspectives” offers valuable insights. This piece explores how technological advancements in robotics are reshaping industries, highlighting the economic implications and strategic considerations businesses must navigate. To delve deeper into how robotics innovations like those from Fanuc are influencing business landscapes, you can read the full article here.

FAQs

What is Fanuc Robotics?

Fanuc Robotics is a division of Fanuc Corporation, a leading global manufacturer of factory automation, robotics, and CNC systems. Fanuc Robotics specializes in industrial robots, automation solutions, welding, painting, and material handling.

What are the main products and solutions offered by Fanuc Robotics?

Fanuc Robotics offers a wide range of industrial robots, including articulated robots, delta robots, SCARA robots, and collaborative robots. They also provide automation solutions for various industries, such as automotive, electronics, food and beverage, and more. Additionally, Fanuc Robotics offers welding, painting, and material handling solutions.

What are the applications of Fanuc Robotics products and solutions?

Fanuc Robotics products and solutions are used in a variety of applications, including assembly, material handling, machine tending, welding, painting, and packaging. They are also used in industries such as automotive manufacturing, electronics, pharmaceuticals, and food and beverage production.

What are the benefits of using Fanuc Robotics products and solutions?

The use of Fanuc Robotics products and solutions can lead to increased productivity, improved quality, reduced cycle times, and enhanced worker safety. Additionally, Fanuc Robotics offers advanced technologies such as vision systems and force sensing that can further enhance the capabilities of their robots.

Where can I find more information about Fanuc Robotics products and solutions?

More information about Fanuc Robotics products and solutions can be found on their official website, as well as through their authorized distributors and partners. Additionally, Fanuc Robotics provides technical support and training for their products and solutions.

Leave a Reply