In the rapidly evolving landscape of technology, IBM Maximo stands out as a robust asset management solution that integrates seamlessly with the Internet of Things (IoT). This powerful combination allows organizations to monitor, manage, and optimize their assets in real-time, leading to enhanced operational efficiency and reduced costs. IBM Maximo is designed to provide comprehensive visibility into asset performance, enabling businesses to make informed decisions based on real-time data.

As industries increasingly adopt IoT technologies, the synergy between IBM Maximo and IoT becomes a game-changer for asset management. The integration of IoT with IBM Maximo empowers organizations to harness the vast amounts of data generated by connected devices.

This data can be analyzed to gain insights into asset health, usage patterns, and m

The integration of IoT technology into asset management systems like IBM Maximo enables real-time monitoring of assets across various industries. IoT sensors can be installed on equipment to collect data on performance metrics such as temperature, vibration, and operational status. This continuous stream of data allows organizations to gain immediate insights into their assets’ health and performance, facilitating timely decision-making.

Real-time asset monitoring not only enhances visibility but also empowers organizations to respond swiftly to potential issues. For instance, if an IoT sensor detects an anomaly in equipment performance, alerts can be generated automatically within IBM Maximo, prompting maintenance teams to investigate before a failure occurs. This proactive approach minimizes downtime and reduces repair costs, ultimately leading to improved productivity and efficiency.

Implementing Predictive Maintenance Strategies with IBM Maximo

| Metrics |

Value |

| Number of assets monitored |

500 |

| Percentage of maintenance cost reduction |

15% |

| Number of predictive maintenance alerts generated |

200 |

| Percentage increase in asset uptime |

10% |

Predictive maintenance is a key strategy that leverages data analytics and machine learning algorithms to forecast when equipment is likely to fail. By integrating predictive maintenance capabilities within IBM Maximo, organizations can transition from reactive maintenance practices to a more strategic approach that optimizes asset performance. This involves analyzing historical data alongside real-time information collected from IoT devices to identify patterns that precede equipment failures.

Implementing predictive maintenance strategies requires a cultural shift within organizations, as it necessitates a commitment to data-driven decision-making. With IBM Maximo’s advanced analytics tools, businesses can create predictive models that inform maintenance schedules based on actual asset conditions rather than arbitrary time intervals. This not only enhances the reliability of equipment but also allows organizations to allocate resources more effectively, ensuring that maintenance activities are performed when they are truly needed.

Harnessing Data Analytics for Improved Asset Performance

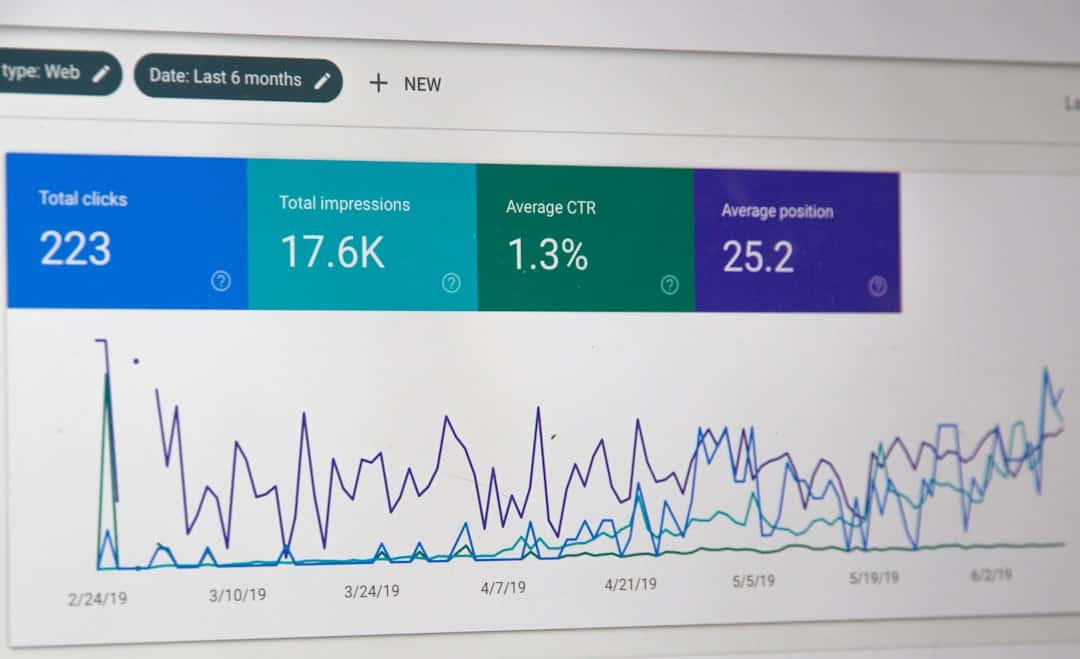

Data analytics plays a crucial role in enhancing asset performance management through IBM Maximo. By harnessing the power of big data analytics, organizations can uncover valuable insights that drive operational improvements. The ability to analyze large datasets enables businesses to identify inefficiencies, optimize resource allocation, and enhance decision-making processes.

IBM Maximo provides a suite of analytics tools that allow users to visualize data trends and generate actionable insights. For example, organizations can analyze historical maintenance records alongside real-time performance data to identify recurring issues or patterns that may indicate underlying problems. By addressing these issues proactively, businesses can improve asset reliability and reduce operational costs significantly.

Integrating IoT with IBM Maximo for Enhanced Efficiency

The integration of IoT with IBM Maximo creates a powerful ecosystem for asset management that enhances overall efficiency. By connecting IoT devices directly to the Maximo platform, organizations can streamline their operations and improve collaboration across teams. This integration allows for seamless data flow between devices and the asset management system, ensuring that all stakeholders have access to the same real-time information.

Enhanced efficiency is achieved through automated workflows and improved communication between departments. For instance, when an IoT sensor detects an issue with an asset, it can trigger automated alerts within IBM Maximo, notifying the relevant maintenance team without manual intervention. This not only speeds up response times but also reduces the likelihood of human error in communication.

As a result, organizations can operate more cohesively and effectively manage their assets.

Case Studies: Successful Implementation of IoT and IBM Maximo

Numerous organizations have successfully implemented IoT solutions in conjunction with IBM Maximo to achieve remarkable results in asset management.

One notable case study involves a large manufacturing company that integrated IoT sensors into its production equipment.

By leveraging real-time data collected through these sensors, the company was able to implement predictive maintenance strategies that reduced unplanned downtime by over 30%.

The insights gained from data analytics allowed them to optimize their maintenance schedules and allocate resources more effectively. Another compelling example comes from the energy sector, where a utility company utilized IBM Maximo alongside IoT technology to monitor its infrastructure more effectively. By deploying sensors across its power generation facilities, the company could track equipment performance in real-time and identify potential failures before they occurred.

This proactive approach not only improved reliability but also resulted in significant cost savings by reducing emergency repairs and extending asset lifecycles.

Future Trends in Asset Performance Management with IBM Maximo and IoT

As technology continues to advance, the future of asset performance management with IBM Maximo and IoT looks promising. One emerging trend is the increased adoption of artificial intelligence (AI) and machine learning algorithms within asset management systems. These technologies will enable organizations to analyze vast datasets more efficiently and develop even more accurate predictive models for maintenance.

Additionally, the rise of edge computing will further enhance the capabilities of IoT devices connected to IBM Maximo. By processing data closer to the source rather than relying solely on centralized cloud systems, organizations can achieve faster response times and reduce latency in decision-making processes. This will be particularly beneficial for industries where real-time monitoring is critical.

In conclusion, the integration of IBM Maximo with IoT technologies represents a significant advancement in asset performance management. By embracing proactive maintenance strategies driven by data analytics and real-time monitoring, organizations can optimize their operations and achieve greater efficiency. As we look ahead, the continued evolution of these technologies promises even more innovative solutions for managing assets effectively in an increasingly connected world.

For those interested in exploring how IoT and data analytics are revolutionizing asset management and operational optimization, a related article worth reading discusses the intersection of blockchain technology with these areas. The article, available on Metaversum, delves into how blockchain can enhance the security and efficiency of IoT devices, which are integral to systems like IBM Maximo. This integration facilitates predictive maintenance and better asset management, crucial for optimizing operations across various industries. You can read more about this topic by visiting Blockchain Technology and Its Impact on Industries.

FAQs

What is IBM Maximo?

IBM Maximo is an enterprise asset management software solution that helps organizations manage their assets, including facilities, equipment, vehicles, and more. It provides tools for asset management, work management, inventory management, and procurement.

How does IBM Maximo utilize IoT for asset management?

IBM Maximo leverages IoT (Internet of Things) technology to connect and collect data from sensors and devices on assets. This data is used to monitor asset performance, predict maintenance needs, and optimize asset operations.

What is predictive maintenance in the context of IBM Maximo?

Predictive maintenance in IBM Maximo involves using data from IoT sensors and other sources to predict when equipment is likely to fail so that maintenance can be performed proactively, reducing downtime and costs.

What are the key features of IBM Maximo?

Key features of IBM Maximo include asset management, work management, inventory management, procurement, mobile access, IoT integration, predictive maintenance, and data analytics for operational optimization.

How does IBM Maximo support data analysis for operational optimization?

IBM Maximo provides tools for analyzing data collected from assets and operations to identify trends, patterns, and opportunities for improvement. This data analysis can help organizations optimize their operations and make data-driven decisions.

Leave a Reply