In the rapidly evolving landscape of technology, Foxconn has emerged as a pivotal player in the integration of artificial intelligence (AI) within industrial settings. Known primarily for its role as a major electronics manufacturer, Foxconn is now leveraging AI to enhance its operational capabilities and redefine manufacturing processes. The company’s commitment to innovation is evident in its strategic investments in AI technologies, which aim to streamline production, improve quality control, and ultimately drive profitability.

As industries worldwide grapple with the challenges of efficiency and scalability, Foxconn’s foray into industrial AI represents a significant shift towards smarter manufacturing solutions. Foxconn’s Industrial AI initiative is not merely a response to market demands; it is a proactive approach to future-proofing its operations. By harnessing the power of AI, the company seeks to create a more agile and responsive manufacturing environment.

This involves the deployment of advanced algorithms, machine learning models, and data analytics tools that can process vast amounts of information in real-time. As a result, Foxconn is positioned to not only meet the current needs of its clients but also anticipate future trends and challenges in the manufacturing sector.

Key Takeaways

- Foxconn Industrial AI is revolutionizing the manufacturing industry with its advanced artificial intelligence technology.

- The impact of Foxconn Industrial AI on manufacturing is significant, leading to increased efficiency, reduced costs, and improved quality control.

- Foxconn Industrial AI is revolutionizing the supply chain by optimizing inventory management, predicting demand, and enhancing logistics processes.

- Artificial intelligence plays a crucial role in Foxconn’s manufacturing processes, enabling predictive maintenance, quality inspection, and process optimization.

- The benefits of Foxconn Industrial AI for efficiency and productivity are evident through reduced downtime, improved production output, and enhanced decision-making capabilities.

The Impact of Foxconn Industrial AI on Manufacturing

The introduction of Foxconn Industrial AI has had a profound impact on the manufacturing landscape. One of the most significant changes is the enhancement of production efficiency. By utilizing AI-driven systems, Foxconn can optimize workflows, reduce downtime, and minimize waste.

This level of insight allows for timely interventions and adjustments, ensuring that production lines operate at peak performance. Moreover, the integration of AI into manufacturing processes has led to improved quality control.

Traditional quality assurance methods often rely on manual inspections, which can be time-consuming and prone to human error. In contrast, AI systems can continuously monitor production outputs, using computer vision and machine learning to detect defects or anomalies in real-time. This not only enhances product quality but also reduces the costs associated with rework and returns.

As a result, Foxconn’s commitment to quality is reinforced, bolstering its reputation as a reliable partner for major tech companies.

How Foxconn Industrial AI is Revolutionizing the Supply Chain

Foxconn’s Industrial AI initiatives extend beyond the factory floor; they are also transforming supply chain management. The company’s use of AI technologies enables it to create a more interconnected and responsive supply chain ecosystem. By analyzing data from suppliers, logistics providers, and market trends, Foxconn can make informed decisions about inventory management, procurement, and distribution strategies.

This data-driven approach allows for greater agility in responding to fluctuations in demand and supply chain disruptions. Additionally, AI-powered predictive analytics play a crucial role in enhancing supply chain visibility. By forecasting demand patterns and potential disruptions, Foxconn can proactively adjust its operations to mitigate risks.

This capability is particularly valuable in today’s globalized economy, where supply chains are often complex and vulnerable to various external factors. With AI at the helm, Foxconn is not only improving its own supply chain efficiency but also setting new standards for the industry as a whole.

The Role of Artificial Intelligence in Foxconn’s Manufacturing Processes

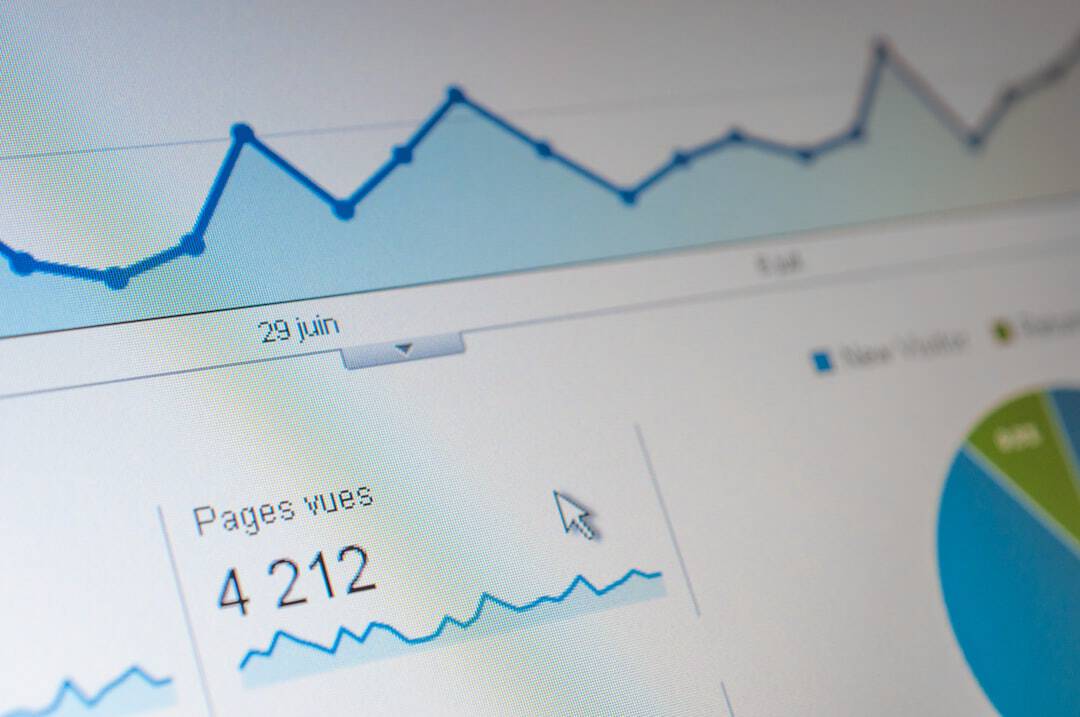

| Metrics | Data |

|---|---|

| Reduction in Defects | 20% |

| Improvement in Production Efficiency | 15% |

| Cost Savings | 10 million |

| Increased Productivity | 25% |

Artificial intelligence serves as the backbone of Foxconn’s manufacturing processes, driving innovation at every level. From automated assembly lines to intelligent robotics, AI technologies are reshaping how products are designed, manufactured, and delivered. For instance, collaborative robots (cobots) equipped with AI capabilities work alongside human operators, enhancing productivity while ensuring safety.

These cobots can learn from their interactions with humans and adapt their actions accordingly, creating a harmonious working environment that maximizes output. Furthermore, AI plays a critical role in predictive maintenance within Foxconn’s facilities. By analyzing data from machinery and equipment, AI systems can predict when maintenance is required before a failure occurs.

As Foxconn continues to refine its manufacturing processes through AI integration, it sets a benchmark for other manufacturers looking to embrace similar technologies.

The Benefits of Foxconn Industrial AI for Efficiency and Productivity

The benefits of implementing Foxconn Industrial AI are manifold, particularly concerning efficiency and productivity. One of the most notable advantages is the reduction in operational costs. By automating routine tasks and optimizing workflows through AI algorithms, Foxconn can allocate resources more effectively and reduce labor costs associated with manual processes.

This financial efficiency allows the company to reinvest in research and development, further driving innovation. In addition to cost savings, Foxconn’s Industrial AI initiatives have led to significant improvements in production speed. With real-time data analysis and automated decision-making processes, production lines can operate at unprecedented speeds without sacrificing quality.

This increased throughput not only meets customer demands more effectively but also enhances overall competitiveness in the market. As other manufacturers observe these advancements, they may be compelled to adopt similar technologies to keep pace with Foxconn’s progress.

Challenges and Limitations of Implementing AI in Manufacturing

Despite the numerous advantages associated with Foxconn Industrial AI, there are challenges and limitations that must be addressed. One significant hurdle is the initial investment required for implementing advanced AI systems. The costs associated with acquiring new technologies, training personnel, and integrating these systems into existing operations can be substantial.

For smaller manufacturers or those with limited resources, this financial barrier may hinder their ability to adopt AI solutions. Moreover, there are concerns regarding data security and privacy when utilizing AI in manufacturing environments. The reliance on vast amounts of data raises questions about how this information is stored, processed, and protected from potential cyber threats.

As manufacturers like Foxconn continue to embrace digital transformation, they must also prioritize robust cybersecurity measures to safeguard sensitive information and maintain customer trust.

The Future of Foxconn Industrial AI and its Potential Impact on the Industry

Looking ahead, the future of Foxconn Industrial AI appears promising as it continues to evolve alongside technological advancements. The company is likely to explore further applications of AI beyond traditional manufacturing processes. For instance, integrating AI with Internet of Things (IoT) devices could lead to even greater levels of automation and data-driven decision-making across the entire production ecosystem.

Additionally, as sustainability becomes an increasingly important focus for industries worldwide, Foxconn’s Industrial AI initiatives may play a crucial role in promoting environmentally friendly practices. By optimizing resource usage and minimizing waste through intelligent systems, Foxconn can contribute to a more sustainable manufacturing model that aligns with global efforts to combat climate change.

The Potential of Foxconn Industrial AI in Shaping the Future of Manufacturing and Supply Chain

In conclusion, Foxconn Industrial AI represents a transformative force within the manufacturing sector and supply chain management. By harnessing advanced technologies such as machine learning and predictive analytics, Foxconn is redefining operational efficiency and setting new standards for quality control. While challenges remain in terms of implementation costs and data security concerns, the potential benefits far outweigh these obstacles.

As industries continue to navigate an increasingly complex landscape marked by rapid technological advancements, Foxconn’s commitment to industrial AI positions it as a leader in shaping the future of manufacturing. The company’s innovative approach not only enhances its own operations but also serves as a blueprint for others seeking to leverage AI for competitive advantage. Ultimately, Foxconn’s journey into industrial AI underscores the importance of embracing technology as a catalyst for growth and sustainability in an ever-evolving marketplace.

Wenn Sie sich für die fortschrittlichen Technologien interessieren, die in der modernen Fertigung eingesetzt werden, wie KI-basierte Fertigung und Qualitätskontrolle, die Foxconn Industrial AI umfasst, könnte Sie auch der Artikel über die Bedeutung und Auswirkungen des Metaversums interessieren. Dieser Artikel bietet Einblicke in die neuesten Entwicklungen im Bereich der digitalen Welten und wie diese Technologien die Art und Weise, wie wir arbeiten und produzieren, revolutionieren könnten. Er bietet eine umfassende Analyse darüber, wie immersive Technologien in verschiedenen Branchen, einschließlich der Fertigungsindustrie, eingesetzt werden könnten, um Effizienz und Produktivität zu steigern.

FAQs

What is Foxconn Industrial AI?

Foxconn Industrial AI is a division of Foxconn Technology Group that focuses on integrating artificial intelligence (AI) into manufacturing processes. It offers AI-based solutions for manufacturing, quality control, production monitoring, supply chain analysis, and performance improvement.

What are the key areas of focus for Foxconn Industrial AI?

Foxconn Industrial AI focuses on KI-basierte Fertigung (AI-based manufacturing), Qualitätskontrolle (quality control), Produktionsüberwachung (production monitoring), Supply-Chain-Analyse (supply chain analysis), and Leistungsverbesserung (performance improvement).

How does Foxconn Industrial AI use AI in manufacturing processes?

Foxconn Industrial AI uses AI to optimize manufacturing processes by analyzing data, predicting equipment failures, improving production efficiency, and automating repetitive tasks. This helps in reducing costs and improving overall productivity.

What are the benefits of using AI in manufacturing and supply chain management?

The use of AI in manufacturing and supply chain management can lead to improved product quality, reduced downtime, predictive maintenance, optimized inventory management, and enhanced decision-making based on real-time data analysis.

How does Foxconn Industrial AI contribute to performance improvement in manufacturing?

Foxconn Industrial AI contributes to performance improvement in manufacturing by leveraging AI to identify areas for optimization, reduce waste, enhance production efficiency, and enable proactive maintenance of equipment. This ultimately leads to improved overall performance and cost savings.

Leave a Reply