In the rapidly evolving landscape of technology, the Internet of Things (IoT) has emerged as a transformative force, particularly in industrial settings. Splunk Industrial IoT stands at the forefront of this revolution, offering organizations the ability to harness vast amounts of data generated by connected devices. By integrating data from sensors, machines, and other industrial assets, Splunk provides a comprehensive platform for monitoring, analyzing, and optimizing operations.

This powerful tool not only enhances operational efficiency but also drives innovation by enabling data-driven decision-making. Splunk Industrial IoT is designed to cater to the unique challenges faced by industries such as manufacturing, energy, and transportation. With its robust analytics capabilities, it empowers organizations to gain insights into their processes, identify inefficiencies, and predict potential fAIlures before they occur.

As industries increasingly adopt smart technologies, the need for a reliable and scalable solution like Splunk becomes paramount. This article delves into the significance of IoT insights in industrial settings, explores how Splunk can unlock real-time data insights, and examines the role of machine learning and AI in enhancing these capabilities.

Key Takeaways

- Splunk Industrial IoT is a powerful platform for unlocking real-time data insights in industrial settings.

- IoT insights are crucial for optimizing operations, improving efficiency, and reducing downtime in industrial environments.

- Splunk Industrial IoT leverages machine learning and AI to analyze and act on data in real time, enabling proactive decision-making.

- Successful case studies demonstrate the impact of Splunk Industrial IoT in improving operational efficiency and reducing costs.

- Security and compliance considerations are essential when handling IoT data in industrial environments, and best practices should be followed when implementing Splunk Industrial IoT.

The Importance of IoT Insights in Industrial Settings

The integration of IoT technology in industrial environments has revolutionized how organizations operate. By connecting machines and devices to the internet, companies can collect and analyze data in real-time, leading to improved decision-making and operational efficiency. The insights derived from this data are invaluable; they allow businesses to monitor performance metrics, track equipment health, and optimize resource allocation.

In an era where downtime can lead to significant financial losses, having access to timely and accurate information is crucial. Moreover, IoT insights facilitate predictive maintenance strategies that can drastically reduce operational costs. By analyzing historical data and identifying patterns, organizations can predict when a machine is likely to fail and schedule maintenance accordingly.

This proactive approach not only minimizes unplanned downtime but also extends the lifespan of equipment. In addition to maintenance benefits, IoT insights can enhance safety protocols by monitoring environmental conditions and alerting personnel to potential hazards. As industries continue to embrace digital transformation, the importance of leveraging IoT insights cannot be overstated.

How Splunk Industrial IoT Can Unlock Real-time Data Insights

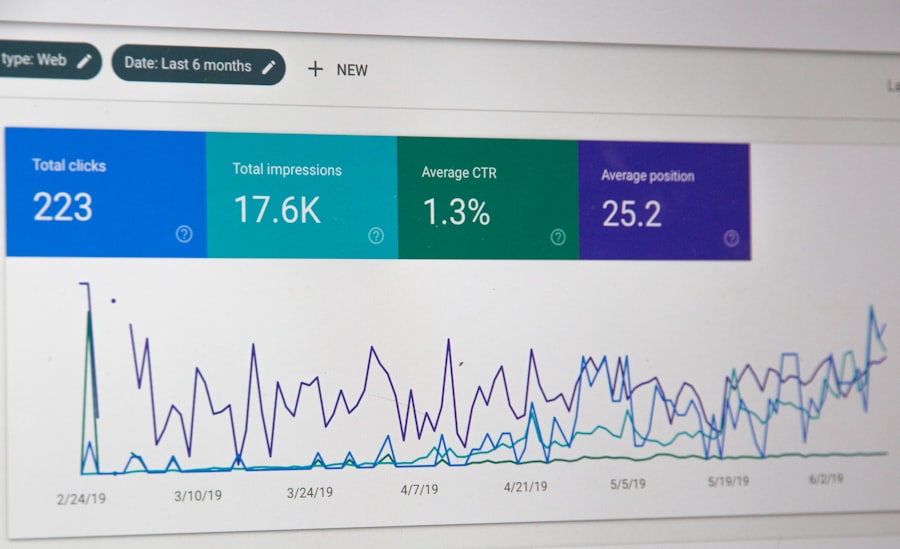

Splunk Industrial IoT excels in its ability to process and analyze vast amounts of data generated by connected devices in real-time. By aggregating data from various sources—such as sensors, machines, and operational systems—Splunk creates a unified view of an organization’s operations. This holistic perspective enables businesses to identify trends, anomalies, and areas for improvement quickly.

The platform’s powerful search capabilities allow users to query data effortlessly, making it easier to extract actionable insights. One of the standout features of Splunk Industrial IoT is its ability to visualize data through intuitive dashboards and reports. These visualizations help stakeholders understand complex data sets at a glance, facilitating informed decision-making across all levels of the organization.

Additionally, Splunk’s real-time alerting system ensures that users are notified of critical events as they occur, allowing for immediate action when necessary. This capability is particularly beneficial in industries where rapid response times are essential for maintaining safety and operational continuity.

Leveraging Machine Learning and AI with Splunk Industrial IoT

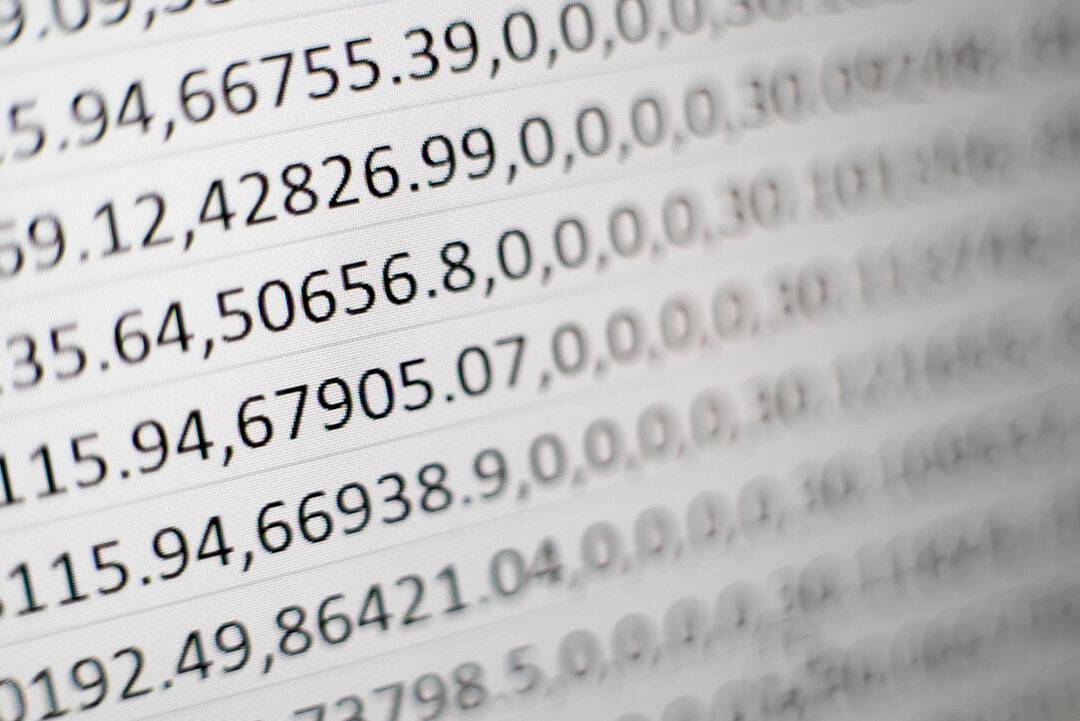

| Metrics | Data |

|---|---|

| Number of Machine Learning models implemented | 10 |

| AI algorithms used for predictive maintenance | Random Forest, Neural Networks |

| Reduction in unplanned downtime | 25% |

| Improvement in equipment efficiency | 15% |

The integration of machine learning (ML) and artificial intelligence (AI) into Splunk Industrial IoT further enhances its analytical capabilities. By employing advanced algorithms, organizations can uncover hidden patterns within their data that may not be immediately apparent through traditional analysis methods. Machine learning models can be trained on historical data to predict future outcomes, enabling businesses to make proactive decisions based on anticipated trends.

AI-driven analytics within Splunk also facilitate anomaly detection, which is crucial for identifying potential issues before they escalate into significant problems. For instance, if a machine begins to operate outside its normal parameters, Splunk can automatically flag this anomaly and alert relevant personnel. This capability not only improves operational efficiency but also enhances safety by reducing the risk of equipment failure or accidents.

Case Studies: Successful Implementation of Splunk Industrial IoT

Numerous organizations have successfully implemented Splunk Industrial IoT to drive operational improvements and achieve significant cost savings. For example, a leading manufacturing company utilized Splunk to monitor its production line in real-time. By analyzing data from various sensors and machines, the company was able to identify bottlenecks in its processes and optimize workflow accordingly.

As a result, they experienced a 20% increase in production efficiency within just a few months of implementation. Another compelling case study involves an energy provider that adopted Splunk Industrial IoT to enhance its predictive maintenance capabilities. By integrating data from thousands of sensors across its infrastructure, the company was able to predict equipment failures with remarkable accuracy.

This proactive approach not only reduced unplanned outages but also saved millions in maintenance costs annually. These case studies illustrate the transformative potential of Splunk Industrial IoT in driving efficiency and innovation across diverse industries.

Security and Compliance Considerations for IoT Data in Industrial Environments

As organizations increasingly rely on IoT technology, security and compliance considerations become paramount. The vast amounts of data generated by connected devices can be vulnerable to cyber threats if not adequately protected. Splunk Industrial IoT addresses these concerns by incorporating robust security features that help safeguard sensitive information.

Compliance with industry regulations is another critical aspect of managing IoT data in industrial environments. Organizations must adhere to various standards related to data privacy and security, depending on their sector.

Splunk provides tools that assist businesses in maintaining compliance by offering audit trails and reporting features that document data access and usage. By prioritizing security and compliance, organizations can confidently leverage the power of IoT without compromising their integrity or exposing themselves to unnecessary risks.

Best Practices for Implementing Splunk Industrial IoT

To maximize the benefits of Splunk Industrial IoT, organizations should follow best practices during implementation. First and foremost, it is essential to define clear objectives for what the organization hopes to achieve with the platform. Whether it’s improving operational efficiency or enhancing predictive maintenance capabilities, having specific goals will guide the implementation process.

Additionally, organizations should invest time in training their staff on how to effectively use Splunk’s features and functionalities. Empowering employees with the knowledge to analyze data and derive insights will foster a culture of data-driven decision-making within the organization. Furthermore, establishing a robust data governance framework is crucial for ensuring data quality and integrity throughout the implementation process.

By adhering to these best practices, organizations can unlock the full potential of Splunk Industrial IoT.

Future Trends and Developments in IoT Insights with Splunk

As technology continues to advance at an unprecedented pace, the future of IoT insights with Splunk looks promising. One emerging trend is the increasing integration of edge computing with IoT solutions. By processing data closer to where it is generated—at the edge—organizations can reduce latency and improve response times significantly.

This shift will enable real-time analytics even in remote locations where connectivity may be limited. Moreover, advancements in AI and machine learning will continue to enhance the capabilities of Splunk Industrial IoT. As algorithms become more sophisticated, organizations will be able to leverage predictive analytics with greater accuracy than ever before.

Additionally, as industries increasingly adopt 5G technology, the volume of data generated by connected devices will skyrocket, necessitating robust solutions like Splunk to manage and analyze this influx effectively. In conclusion, Splunk Industrial IoT represents a powerful tool for organizations seeking to harness the potential of connected devices in industrial settings. By providing real-time insights, leveraging machine learning and AI capabilities, and addressing security concerns, Splunk empowers businesses to optimize their operations and drive innovation in an increasingly competitive landscape.

As we look ahead, it is clear that the future of IoT insights will be shaped by continued advancements in technology and an unwavering commitment to leveraging data for strategic advantage.

For those interested in exploring further into the realms of IoT analysis, operational monitoring, product optimization, predictive maintenance, and logistics management, similar to the capabilities offered by Splunk Industrial IoT, I recommend reading an insightful article available on the Metaversum website. This article delves into the historical evolution of the metaverse and its implications on modern technologies, including IoT. It provides a comprehensive overview of how evolving digital environments are influencing industrial applications and operational technologies. You can read the full article by visiting Historical Evolution of the Metaverse. This resource is particularly useful for understanding the broader context in which IoT technologies are developing and being applied across various industries.

FAQs

What is Splunk Industrial IoT?

Splunk Industrial IoT is a platform that provides IoT analytics, operational monitoring, product optimization, predictive maintenance, and logistics management capabilities for industrial organizations.

What are the key features of Splunk Industrial IoT?

The key features of Splunk Industrial IoT include IoT data ingestion and analysis, real-time operational monitoring, predictive maintenance capabilities, product optimization tools, and logistics management solutions.

How does Splunk Industrial IoT help with IoT analytics?

Splunk Industrial IoT helps with IoT analytics by enabling organizations to ingest and analyze large volumes of IoT data from industrial equipment, sensors, and devices. It provides real-time insights and actionable intelligence to improve operational efficiency and performance.

What is predictive maintenance and how does Splunk Industrial IoT support it?

Predictive maintenance is a proactive maintenance strategy that uses data and analytics to predict when equipment is likely to fail. Splunk Industrial IoT supports predictive maintenance by analyzing equipment data to identify patterns and anomalies that indicate potential issues, allowing organizations to take preventive actions before failures occur.

How does Splunk Industrial IoT help with operational monitoring?

Splunk Industrial IoT helps with operational monitoring by providing real-time visibility into industrial processes, equipment performance, and production metrics. It enables organizations to monitor and analyze operational data to identify inefficiencies, bottlenecks, and opportunities for improvement.

What are the benefits of using Splunk Industrial IoT for logistics management?

Using Splunk Industrial IoT for logistics management enables organizations to optimize supply chain operations, track inventory, monitor transportation routes, and improve overall logistics efficiency. It provides real-time insights and visibility into the movement of goods and materials across the supply chain.

Leave a Reply