In the ever-evolving landscape of technology, advanced robotics has emerged as a transformative force in precision manufacturing and assembly. This field, characterized by the integration of sophisticated robotic systems into production lines, is reshaping how industries operate. The advent of these intelligent machines has not only enhanced efficiency but has also redefined the standards of quality and precision in manufacturing processes.

As industries strive to meet the demands of an increasingly competitive market, the adoption of advanced robotics is becoming not just an option but a necessity. The integration of robotics into manufacturing and assembly processes is driven by the need for higher productivity, reduced operational costs, and improved product quality. With the ability to perform repetitive tasks with unparalleled accuracy, advanced robots are capable of executing complex operations that were once thought to be the exclusive domain of human workers.

As we delve deeper into this topic, we will explore the myriad benefits, types of solutions avAIlable, and the challenges that accompany the implementation of advanced robotics in precision manufacturing and assembly.

Key Takeaways

- Advanced robotics in precision manufacturing and assembly is revolutionizing the industry by increasing efficiency, accuracy, and productivity.

- The benefits of advanced robotics in precision manufacturing and assembly include improved quality control, reduced labor costs, increased production speed, and enhanced worker safety.

- Types of advanced robotics solutions for precision manufacturing and assembly include industrial robots, collaborative robots, automated guided vehicles, and automated assembly systems.

- Case studies of successful implementation of advanced robotics in precision manufacturing and assembly demonstrate significant improvements in production output, product quality, and cost savings.

- Challenges and limitations of advanced robotics in precision manufacturing and assembly include high initial investment costs, complex integration processes, and the need for skilled technicians to operate and maintain the robotic systems.

- Future trends and innovations in advanced robotics for precision manufacturing and assembly include the development of more flexible and adaptable robotic systems, the integration of artificial intelligence and machine learning, and the use of advanced sensors for improved precision and accuracy.

- Considerations for implementing advanced robotics in precision manufacturing and assembly include conducting a thorough cost-benefit analysis, ensuring proper training for employees, and addressing potential safety concerns.

- In conclusion, the impact of advanced robotics on precision manufacturing and assembly is undeniable, as it continues to drive improvements in efficiency, quality, and competitiveness in the industry.

Benefits of Advanced Robotics in Precision Manufacturing and Assembly

The benefits of advanced robotics in precision manufacturing and assembly are manifold, significantly impacting productivity and operational efficiency. One of the most notable advantages is the ability to operate continuously without fatigue.

This continuous operation not only maximizes production capacity but also allows companies to respond swiftly to market demands, thereby enhancing their competitive edge. Moreover, advanced robotics contributes to improved quality control. With their high precision and consistency, robots minimize the risk of human error, ensuring that each product meets stringent quality standards.

This level of accuracy is particularly crucial in industries where even minor deviations can lead to significant issues down the line. Additionally, the integration of advanced sensors and machine learning algorithms enables robots to adapt to variations in production processes, further enhancing their ability to maintain quality over time.

Types of Advanced Robotics Solutions for Precision Manufacturing and Assembly

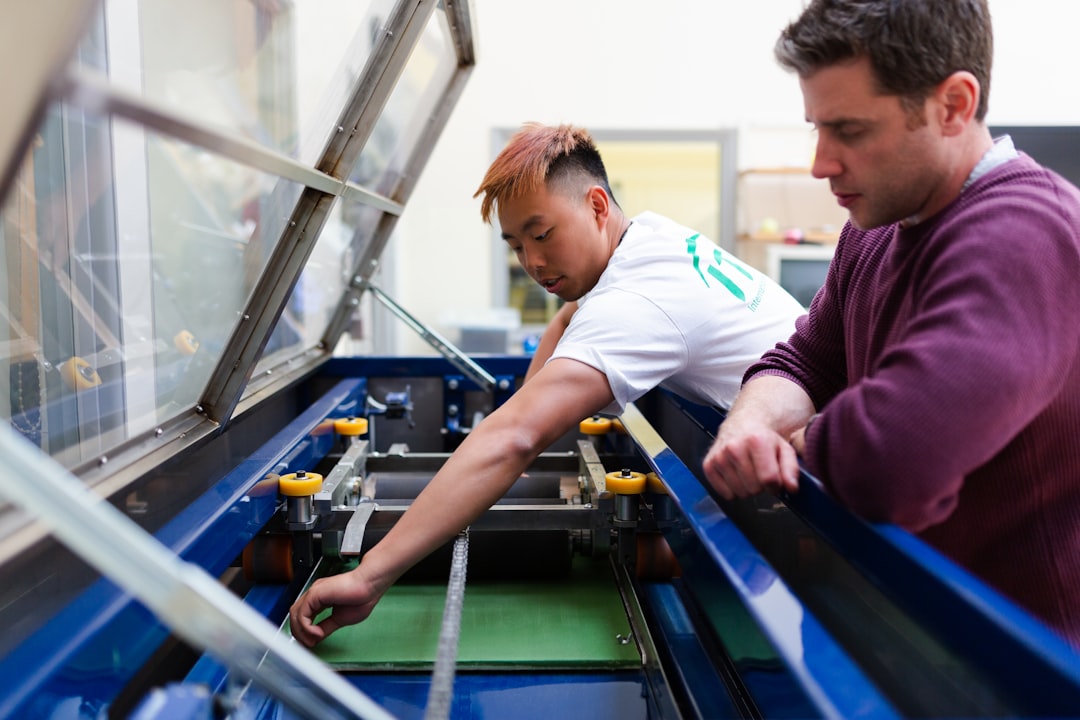

The landscape of advanced robotics solutions for precision manufacturing and assembly is diverse, encompassing a range of technologies tailored to meet specific industry needs. One prominent category is collaborative robots, or cobots, which are designed to work alongside human operators. These robots are equipped with advanced safety features that allow them to operate in close proximity to humans without compromising safety.

Cobots are particularly beneficial in assembly tasks where human dexterity is required, as they can assist workers by handling repetitive or physically demanding tasks. Another significant type of advanced robotics solution is autonomous mobile robots (AMRs). These robots are designed for material handling and logistics within manufacturing facilities.

Equipped with sophisticated navigation systems and sensors, AMRs can transport materials between different areas of a factory without human intervention. This capability not only streamlines operations but also reduces the risk of accidents associated with manual material handling. Furthermore, robotic arms equipped with advanced end-effectors are widely used for tasks such as welding, painting, and assembly, showcasing the versatility of robotics in various manufacturing processes.

Case Studies of Successful Implementation of Advanced Robotics in Precision Manufacturing and Assembly

| Company | Robotics Implementation | Impact |

|---|---|---|

| BMW | Utilized advanced robotics for car assembly | Increased production efficiency by 20% |

| Fanuc | Implemented robotic arms for precision manufacturing | Reduced error rate by 15% |

| ABB | Integrated robotics for electronics assembly | Improved product quality and consistency |

Numerous companies have successfully integrated advanced robotics into their manufacturing processes, yielding impressive results. For instance, a leading automotive manufacturer implemented a fleet of collaborative robots on its assembly line. These cobots were tasked with assisting human workers in assembling complex components while ensuring precision and speed.

The result was a significant reduction in assembly time and an increase in overall productivity. Additionally, the company reported a marked improvement in employee satisfaction as workers were relieved from monotonous tasks and could focus on more skilled activities. Another compelling case study involves an electronics manufacturer that adopted autonomous mobile robots for its logistics operations.

By deploying AMRs to transport components between production stations, the company was able to optimize its workflow significantly. The robots navigated through the facility autonomously, reducing bottlenecks and ensuring timely delivery of materials to the assembly line. This implementation not only enhanced operational efficiency but also led to a reduction in labor costs associated with manual material handling.

Challenges and Limitations of Advanced Robotics in Precision Manufacturing and Assembly

Despite the numerous advantages offered by advanced robotics, several challenges and limitations must be addressed for successful implementation in precision manufacturing and assembly. One significant hurdle is the initial investment required for robotic systems. The cost of acquiring advanced robots, along with the necessary infrastructure modifications and training for personnel, can be substantial.

For many small to medium-sized enterprises (SMEs), this upfront investment may pose a barrier to entry. Additionally, there are concerns regarding job displacement as automation becomes more prevalent in manufacturing environments. While robots can enhance productivity and efficiency, they may also lead to a reduction in the workforce required for certain tasks.

This shift necessitates a careful consideration of workforce retraining and upskilling programs to ensure that employees can transition into new roles that complement robotic systems rather than compete with them.

Future Trends and Innovations in Advanced Robotics for Precision Manufacturing and Assembly

The future of advanced robotics in precision manufacturing and assembly is poised for remarkable innovations that will further enhance capabilities and efficiencies. One emerging trend is the integration of artificial intelligence (AI) with robotic systems. By leveraging AI algorithms, robots can learn from their environments and adapt their behaviors based on real-time data analysis.

This capability will enable more sophisticated decision-making processes, allowing robots to optimize their operations dynamically. Another exciting development is the advancement of soft robotics technology. Unlike traditional rigid robots, soft robots are made from flexible materials that allow them to handle delicate components without causing damage.

This innovation opens up new possibilities for applications in industries such as food processing and electronics assembly, where precision handling is critical. As these technologies continue to evolve, we can expect to see even greater levels of automation and efficiency in precision manufacturing processes.

Considerations for Implementing Advanced Robotics in Precision Manufacturing and Assembly

When considering the implementation of advanced robotics in precision manufacturing and assembly, several key factors must be taken into account. First and foremost is the assessment of specific operational needs and objectives. Companies should conduct a thorough analysis of their production processes to identify areas where robotics can provide the most significant impact.

This assessment will help determine the type of robotic solutions that align best with their goals. Furthermore, it is essential to prioritize employee training and engagement throughout the implementation process. Ensuring that workers are equipped with the necessary skills to operate alongside robotic systems is crucial for maximizing productivity and minimizing resistance to change.

By fostering a culture of collaboration between humans and robots, companies can create an environment where both can thrive.

The Impact of Advanced Robotics on Precision Manufacturing and Assembly

In conclusion, advanced robotics has undeniably transformed precision manufacturing and assembly processes across various industries. The benefits of increased efficiency, improved quality control, and enhanced productivity are driving companies to adopt these technologies at an unprecedented rate. As we have explored through case studies and discussions on future trends, it is clear that advanced robotics will continue to play a pivotal role in shaping the future of manufacturing.

However, it is essential for organizations to navigate the challenges associated with implementation thoughtfully. By addressing concerns related to investment costs and workforce displacement while prioritizing employee training, companies can harness the full potential of advanced robotics. As technology continues to advance, we can anticipate even more innovative solutions that will further revolutionize precision manufacturing and assembly, ultimately leading to a more efficient and productive industrial landscape.

For those interested in the intersection of advanced robotics and emerging digital environments, a related article worth exploring is “Metaverse and Industries: Entertainment and Media in the Metaverse” available at Metaversum.it. This article delves into how technologies like those developed by KUKA Robotics, which are pivotal in precision assembly, pick-and-place tasks, and laser cutting, could be integrated within the Metaverse to enhance virtual simulations of manufacturing processes. Such integrations could potentially revolutionize training, remote operation, and even the design phase of manufacturing in various industries, including entertainment and media.

FAQs

What is KUKA Robotics?

KUKA Robotics is a German manufacturer of industrial robots and solutions for factory automation.

What kind of solutions does KUKA Robotics offer?

KUKA Robotics offers robot solutions for manufacturing processes, precision assembly, pick-and-place tasks, and laser cutting.

What are some examples of applications for KUKA Robotics’ solutions?

KUKA Robotics’ solutions can be used in industries such as automotive manufacturing, electronics assembly, metalworking, and logistics.

What are the benefits of using KUKA Robotics’ solutions?

Using KUKA Robotics’ solutions can lead to increased productivity, improved quality, and reduced labor costs in manufacturing processes.

Where are KUKA Robotics’ solutions used?

KUKA Robotics’ solutions are used in factories and manufacturing facilities around the world, across various industries.

Leave a Reply