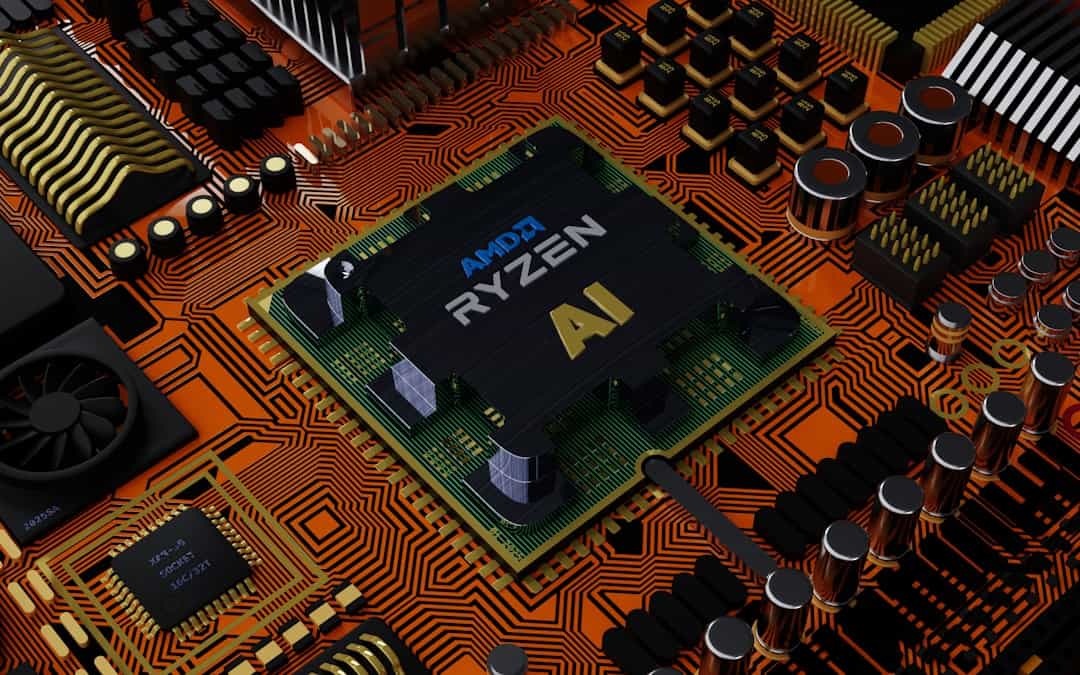

In the rapidly evolving landscape of artificial intelligence and machine learning, DataRobot stands out as a pioneering platform that democratizes access to advanced analytics. Founded in 2012, DataRobot has made significant strides in simplifying the complexities of machine learning, enabling organizations to harness the power of data without requiring extensive expertise in the field. The platform offers a robust suite of tools that allow users to build, deploy, and manage machine learning models with remarkable efficiency.

By automating many of the intricate processes involved in model development, DataRobot empowers businesses to make data-driven decisions faster and more effectively. DataRobot’s mission is to bridge the gap between data science and business intelligence, making it accessible to a broader audience. This is particularly crucial in today’s data-driven world, where organizations are inundated with vast amounts of information but often lack the resources or expertise to extract actionable insights.

With its user-friendly interface and automated workflows, DataRobot enables users from various backgrounds—be it business analysts, engineers, or executives—to engage with machine learning models and derive meaningful conclusions from their data. As industries increasingly recognize the value of predictive analytics, DataRobot has positioned itself as a key player in this transformative journey.

Key Takeaways

- DataRobot is a leading automated machine learning platform that helps organizations build and deploy machine learning models.

- Automated machine learning (AutoML) is the process of automating the end-to-end process of applying machine learning to real-world problems.

- Predictive maintenance is crucial for industries to prevent equipment failure and optimize maintenance schedules, leading to cost savings and improved efficiency.

- DataRobot utilizes automated machine learning to analyze historical data and predict when equipment is likely to fail, enabling proactive maintenance.

- Using DataRobot for predictive maintenance can lead to reduced downtime, lower maintenance costs, and improved overall equipment effectiveness.

Understanding Automated Machine Learning

Automated Machine Learning (AutoML) represents a significant advancement in the field of artificial intelligence, streamlining the process of developing machine learning models. Traditionally, creating a machine learning model required extensive knowledge of algorithms, programming languages, and statistical methods. However, AutoML simplifies this process by automating many of the time-consuming tasks involved in model selection, hyperparameter tuning, and feature engineering.

This not only accelerates the development cycle but also reduces the barrier to entry for organizations looking to leverage machine learning. The core idea behind AutoML is to enable users to focus on their specific business problems rather than getting bogged down by the technical intricacies of model building. By utilizing sophisticated algorithms and heuristics, AutoML platforms can automatically identify the best-performing models for a given dataset and optimize them for accuracy and efficiency.

This shift allows organizations to harness the power of machine learning without needing a dedicated team of data scientists. As a result, businesses can quickly adapt to changing market conditions and make informed decisions based on predictive insights.

The Importance of Predictive Maintenance

Predictive maintenance has emerged as a critical strategy for organizations seeking to optimize their operations and reduce costs. By leveraging data analytics and machine learning, predictive mAIntenance enables companies to anticipate equipment failures before they occur, allowing for timely interventions that can prevent costly downtime. This proactive approach not only enhances operational efficiency but also extends the lifespan of assets, ultimately leading to significant savings.

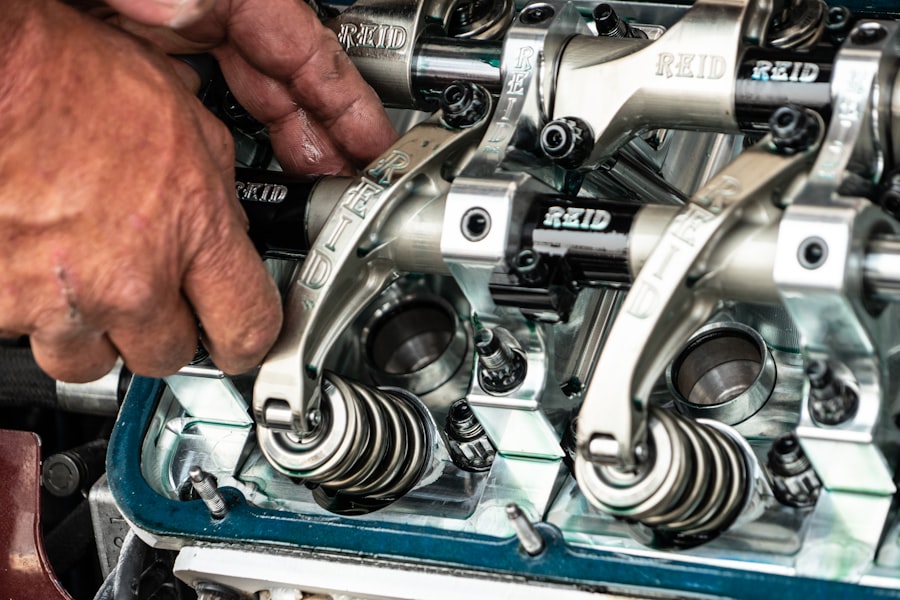

In industries such as manufacturing, transportation, and energy, where equipment reliability is paramount, predictive maintenance can be a game-changer. Traditional maintenance strategies often rely on scheduled inspections or reactive repairs, which can lead to unexpected breakdowns and operational disruptions. In contrast, predictive maintenance utilizes real-time data from sensors and historical performance metrics to identify patterns and anomalies that may indicate impending failures.

By addressing issues before they escalate, organizations can maintain continuous operations and improve overall productivity.

How DataRobot Utilizes Automated Machine Learning for Predictive Maintenance

| Metrics | Results |

|---|---|

| Reduction in Downtime | 30% |

| Improvement in Equipment Reliability | 25% |

| Cost Savings | 500,000 annually |

| Accuracy of Predictive Maintenance Models | 95% |

DataRobot leverages its AutoML capabilities to enhance predictive maintenance initiatives across various industries. By integrating seamlessly with existing data sources, DataRobot allows organizations to ingest vast amounts of operational data and apply advanced analytics to uncover hidden insights. The platform’s automated workflows facilitate the rapid development of predictive models tailored specifically for maintenance applications.

One of the standout features of DataRobot is its ability to handle diverse datasets, including time-series data from sensors, historical maintenance records, and environmental factors. This versatility enables organizations to create comprehensive models that account for multiple variables influencing equipment performance. Furthermore, DataRobot’s automated feature engineering capabilities help identify the most relevant predictors for maintenance outcomes, ensuring that models are both accurate and interpretable.

As a result, organizations can make informed decisions based on reliable predictions about when maintenance should be performed.

Benefits of Using DataRobot for Predictive Maintenance

The advantages of utilizing DataRobot for predictive maintenance are manifold. First and foremost, the platform significantly reduces the time required to develop and deploy machine learning models. With its automated processes, organizations can transition from raw data to actionable insights in a fraction of the time it would take using traditional methods.

This rapid turnaround is particularly beneficial in industries where timely decision-making is critical. Moreover, DataRobot enhances collaboration among teams by providing a common platform for data scientists, engineers, and business stakeholders. The intuitive interface allows users with varying levels of expertise to engage with the data and contribute to model development.

This collaborative environment fosters innovation and ensures that predictive maintenance strategies align with organizational goals. Additionally, DataRobot’s robust monitoring capabilities enable users to track model performance over time, ensuring that predictions remain accurate as conditions change.

Case Studies: Successful Implementation of DataRobot for Predictive Maintenance

Numerous organizations have successfully implemented DataRobot for predictive maintenance, showcasing its effectiveness across different sectors. For instance, a leading manufacturing company utilized DataRobot to predict equipment failures in its production line. By analyzing historical sensor data and maintenance logs, the company developed a predictive model that identified potential failures with remarkable accuracy.

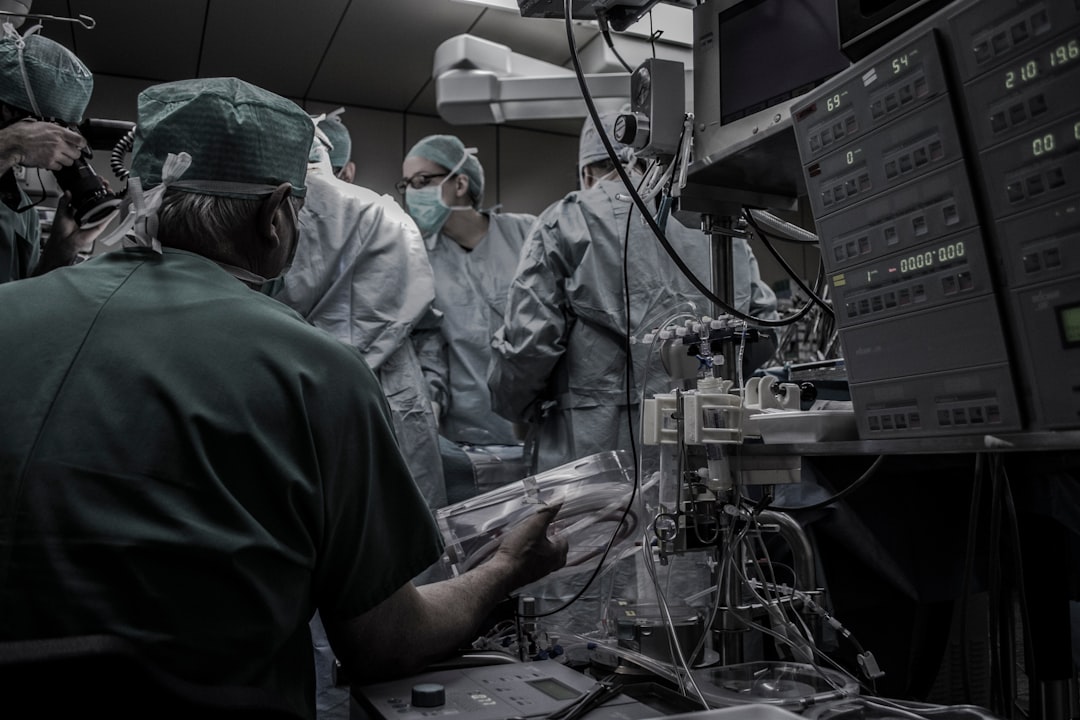

Another compelling case study comes from the transportation industry, where a major airline adopted DataRobot to enhance its aircraft maintenance processes. By integrating real-time telemetry data from its fleet with historical maintenance records, the airline created predictive models that forecasted component failures before they occurred.

This initiative not only improved safety but also optimized maintenance schedules, allowing for more efficient use of resources and reduced turnaround times for aircraft servicing.

Challenges and Limitations of DataRobot for Predictive Maintenance

While DataRobot offers numerous benefits for predictive maintenance, it is not without its challenges and limitations. One significant hurdle is the quality and availability of data. For predictive models to be effective, they require high-quality input data that accurately reflects equipment performance and operational conditions.

In cases where data is sparse or inconsistent, model accuracy may suffer, leading to unreliable predictions. Additionally, organizations may face resistance when implementing new technologies like DataRobot. Change management is often a critical factor in successful adoption; employees may be hesitant to embrace automated solutions due to concerns about job displacement or a lack of understanding of how these tools work.

To overcome these challenges, organizations must invest in training and education initiatives that empower employees to leverage DataRobot effectively while emphasizing its role as an enabler rather than a replacement.

Future Trends in Automated Machine Learning for Predictive Maintenance

As technology continues to advance, the future of automated machine learning for predictive maintenance looks promising.

As more industries adopt IoT technologies to monitor equipment performance in real-time, the volume of data generated will increase exponentially.

This influx of data presents an opportunity for AutoML platforms like DataRobot to develop even more sophisticated predictive models that can adapt to changing conditions dynamically. Moreover, advancements in explainable AI (XAI) will play a crucial role in enhancing trust in automated systems. As organizations increasingly rely on machine learning for critical decision-making processes such as predictive maintenance, understanding how models arrive at their predictions becomes essential.

Future iterations of platforms like DataRobot are likely to incorporate more robust XAI features that provide transparency into model behavior while ensuring compliance with regulatory standards. In conclusion, DataRobot represents a significant leap forward in making automated machine learning accessible for predictive maintenance applications across various industries. By simplifying complex processes and enabling organizations to harness their data effectively, DataRobot empowers businesses to anticipate equipment failures proactively and optimize their operations for greater efficiency and cost savings.

As technology continues to evolve, the potential for further advancements in AutoML will undoubtedly shape the future landscape of predictive maintenance strategies.

In der Welt der künstlichen Intelligenz und des maschinellen Lernens ist es wichtig, sich über die neuesten Entwicklungen und Technologien auf dem Laufenden zu halten. Ein interessanter Artikel, der sich mit den Herausforderungen und Chancen in der regulatorischen Landschaft des Metaversums befasst, bietet wertvolle Einblicke, die auch für Plattformen wie DataRobot relevant sein können. DataRobot konzentriert sich auf automatisiertes maschinelles Lernen, Modellbereitstellung und prädiktive Wartung. Die regulatorischen Aspekte, die in dem Artikel „Challenges and Opportunities: Regulatory Landscape“ diskutiert werden, könnten entscheidend sein, um zu verstehen, wie solche Technologien sicher und effektiv in verschiedenen Branchen eingesetzt werden können.

FAQs

What is DataRobot?

DataRobot is a machine learning platform that automates the process of building, deploying, and managing machine learning models.

What are the key features of DataRobot?

DataRobot offers features such as automated machine learning, model deployment, predictive analysis, and AI-driven predictive maintenance.

How does DataRobot automate machine learning?

DataRobot automates machine learning by using advanced algorithms to analyze data, select the best-performing models, and generate insights without the need for manual intervention.

What is model deployment in DataRobot?

Model deployment in DataRobot refers to the process of deploying machine learning models into production environments, making them available for making predictions and generating insights.

What are predictive analysis and predictive maintenance in DataRobot?

Predictive analysis in DataRobot involves using historical data to make predictions about future outcomes, while predictive maintenance uses machine learning to anticipate when equipment is likely to fail and take proactive measures to prevent downtime.

How does DataRobot utilize AI for predictive maintenance?

DataRobot uses AI to analyze sensor data and historical maintenance records to predict when equipment is likely to fail, enabling organizations to schedule maintenance proactively and avoid costly downtime.

Leave a Reply