In the ever-evolving landscape of warehouse logistics, Amazon Robotics stands out as a pioneering force that has redefined how goods are stored, retrieved, and shipped. Originally known as Kiva Systems, the company was acquired by Amazon in 2012, marking a significant shift in the e-commerce giant’s approach to fulfillment. The integration of robotics into Amazon’s warehouses has not only streamlined operations but has also set a new standard for efficiency in the logistics industry.

With a fleet of autonomous mobile robots working alongside human employees, Amazon has created a symbiotic relationship that enhances productivity while minimizing errors. The deployment of Amazon Robotics is a testament to the company’s commitment to innovation. These robots are designed to navigate complex warehouse environments, transporting shelves filled with products directly to human pickers.

This approach eliminates the need for workers to traverse vast distances within the warehouse, significantly reducing the time it takes to fulfill orders. As e-commerce continues to grow at an unprecedented rate, the importance of such technological advancements cannot be overstated. Amazon Robotics is not just a glimpse into the future of logistics; it is a current reality that is reshaping how businesses operate in an increasingly competitive market.

The introduction of Amazon Robotics has had a profound impact on efficiency and productivity within warehouse operations. By automating the movement of goods, Amazon has drastically reduced the time required for order fulfillment.

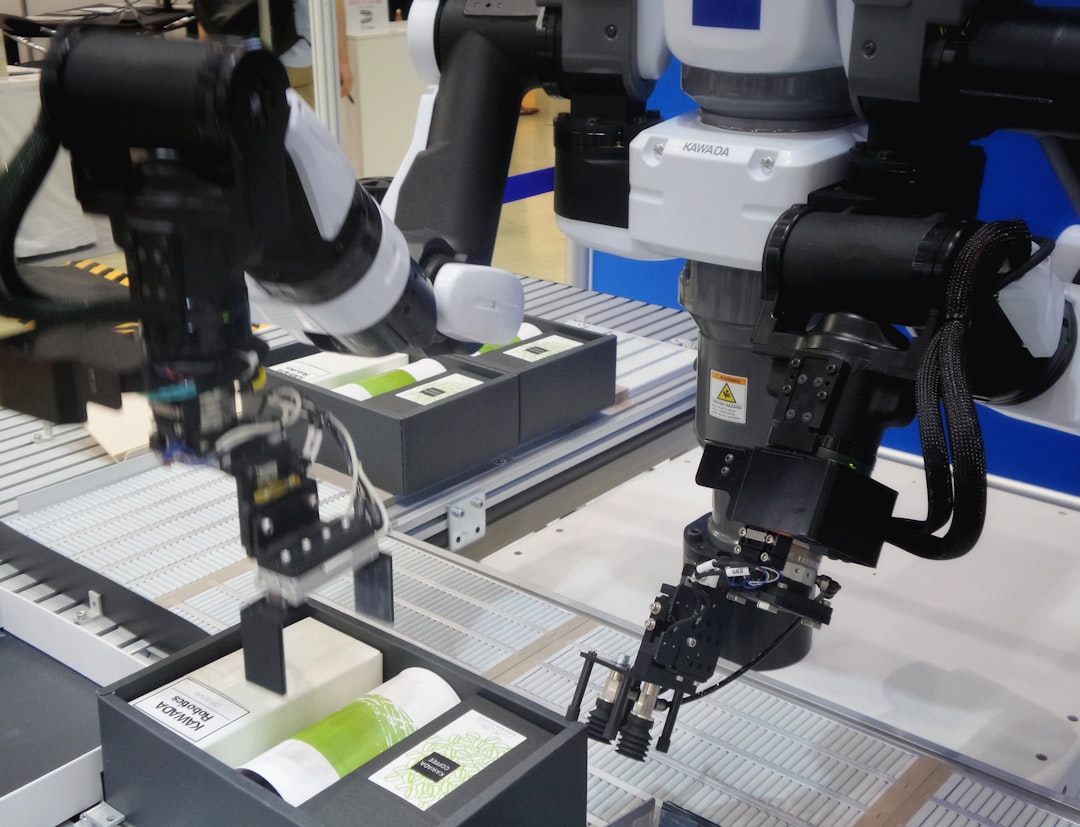

In contrast, Amazon’s robots can quickly transport entire shelves of products to human workers, who can then pick items more efficiently. This not only speeds up the picking process but also allows for a higher volume of orders to be processed in a shorter amount of time. Moreover, the use of robotics has led to a significant reduction in operational costs.

With robots handling repetitive tasks, companies can allocate human resources to more complex roles that require critical thinking and problem-solving skills. This shift not only enhances job satisfaction among employees but also fosters a more dynamic work environment.

As a result, Amazon has been able to maint

Artificial intelligence (AI) plays a crucial role in the functionality and effectiveness of Amazon Robotics. The robots are equipped with advanced algorithms that enable them to navigate their environment autonomously, avoiding obstacles and optimizing their routes in real-time. This capability is essential in a bustling warehouse where the layout can change frequently due to the constant influx of new products and shifting inventory.

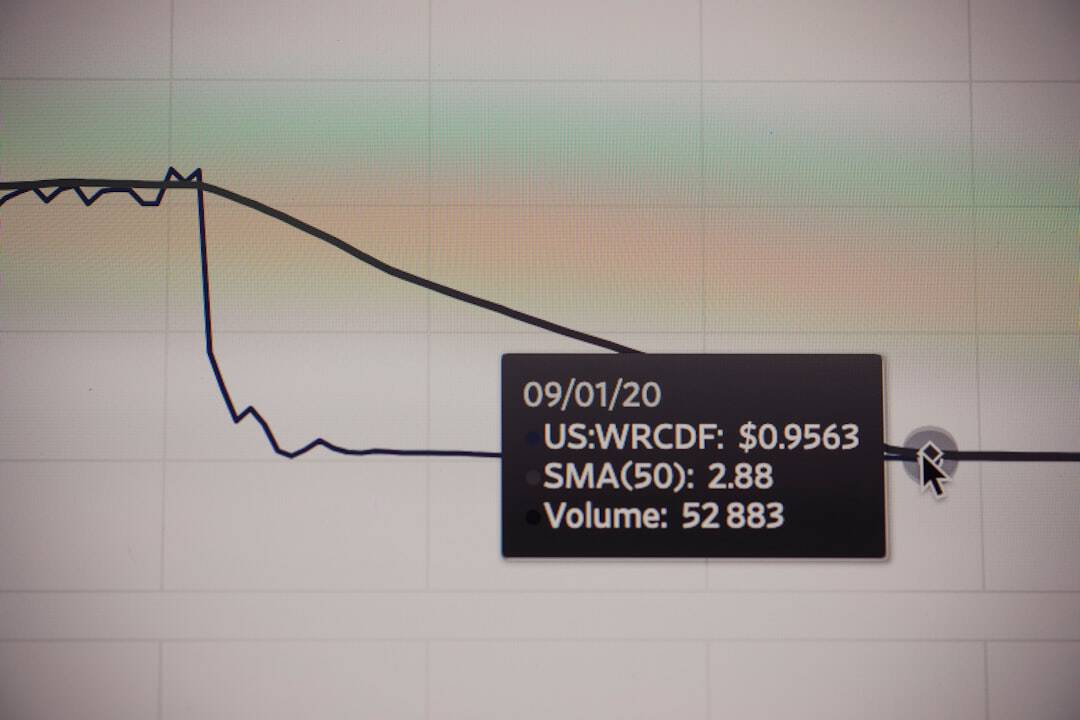

AI allows these robots to learn from their experiences, improving their performance over time and adapting to new challenges as they arise. Additionally, AI enhances the decision-making processes within Amazon’s logistics operations. By analyzing vast amounts of data related to inventory levels, order patterns, and customer preferences, AI systems can predict demand and optimize stock levels accordingly.

This predictive capability ensures that popular items are readily available while minimizing excess inventory that can lead to increased storage costs. The integration of AI into Amazon Robotics not only streamlines operations but also provides valuable insights that drive strategic decision-making across the organization.

Advantages and Challenges of Implementing Amazon Robotics in Warehouse Logistics

| Advantages |

Challenges |

| Increased efficiency |

Initial implementation cost |

| Improved accuracy |

Training employees to work with robots |

| Reduced labor costs |

Integration with existing warehouse systems |

| 24/7 operation |

Maintenance and repair of robots |

The advantages of implementing Amazon Robotics in warehouse logistics are manifold. One of the most significant benefits is the increased speed and accuracy of order fulfillment. With robots handling the heavy lifting and transportation of goods, human workers can focus on tasks that require more nuanced skills, such as quality control and customer service.

This division of labor leads to a more efficient workflow and ultimately results in higher customer satisfaction rates. However, the implementation of robotics is not without its challenges. One major concern is the initial investment required for technology acquisition and infrastructure modification.

Upgrading existing warehouses to accommodate robotic systems can be costly and time-consuming. Additionally, there is the potential for workforce displacement as automation takes over certain tasks traditionally performed by humans. Companies must navigate these challenges carefully, balancing the benefits of automation with the need for a skilled workforce that can adapt to new roles within the organization.

The Future of Warehouse Logistics with Amazon Robotics

As we look toward the future, it is clear that Amazon Robotics will continue to play a pivotal role in shaping warehouse logistics. The ongoing advancements in robotics technology and artificial intelligence promise even greater efficiencies and capabilities. For instance, future iterations of Amazon’s robots may incorporate enhanced machine learning algorithms that allow them to predict and respond to changes in their environment with even greater agility.

This could lead to fully autonomous warehouses where robots manage inventory and fulfill orders with minimal human intervention. Moreover, as consumer expectations evolve, so too will the demands placed on logistics operations. The rise of same-day delivery services has created an urgent need for faster processing times and more efficient supply chains.

Amazon Robotics is well-positioned to meet these challenges head-on, leveraging its technology to ensure that products are delivered quickly and accurately. The future of warehouse logistics is not just about automation; it is about creating an ecosystem where technology and human ingenuity work together seamlessly.

Case Studies of Successful Implementation of Amazon Robotics

Several case studies illustrate the successful implementation of Amazon Robotics across various fulfillment centers. One notable example is the company’s fulfillment center in Robbinsville, New Jersey, which utilizes a fleet of over 3,000 robots. This facility has achieved remarkable efficiency gains since its opening, processing thousands of orders daily with minimal delays.

The integration of robotics has allowed Amazon to maintain its promise of fast delivery times while managing an ever-increasing volume of orders. Another compelling case study can be found in Amazon’s fulfillment center in Tracy, California. Here, robots work alongside human employees in a highly coordinated manner, demonstrating how automation can enhance rather than replace human labor.

Workers report higher job satisfaction due to reduced physical strain and increased focus on value-added tasks. This collaborative approach serves as a model for other companies looking to implement similar technologies while maintaining a skilled workforce.

The Integration of Amazon Robotics with Human Workers in Warehouse Logistics

The integration of Amazon Robotics with human workers represents a paradigm shift in warehouse logistics. Rather than viewing automation as a threat to employment, Amazon has embraced a model where robots complement human capabilities. This collaboration allows workers to engage in more meaningful tasks while robots handle repetitive or physically demanding duties.

For instance, while robots transport shelves filled with products, human employees can concentrate on quality checks and customer service interactions. Training programs have been developed to ensure that workers are equipped with the skills necessary to thrive in this new environment. Employees are encouraged to learn about robotics technology and how it can enhance their roles within the company.

This proactive approach not only alleviates fears surrounding job displacement but also fosters a culture of innovation where employees feel empowered to contribute ideas for further improvements in operations.

The Potential of Amazon Robotics to Revolutionize Warehouse Logistics

In conclusion, Amazon Robotics holds immense potential to revolutionize warehouse logistics as we know it today. By harnessing the power of automation and artificial intelligence, Amazon has set a new benchmark for efficiency and productivity within the industry. The successful integration of robotics with human labor demonstrates that technology can enhance rather than replace traditional roles, creating a more dynamic and responsive workforce.

As we move forward into an era defined by rapid technological advancements, it is clear that companies must adapt or risk falling behind. The lessons learned from Amazon’s implementation of robotics serve as valuable insights for businesses across various sectors looking to optimize their operations. With continued investment in innovation and a commitment to collaboration between humans and machines, the future of warehouse logistics promises to be both exciting and transformative.

For those interested in the intersection of advanced technology and logistics, particularly in the context of Amazon Robotics and its impact on warehouse automation, logistics, and order fulfillment, a related article worth exploring is on the Metaversum website. This article discusses the broader implications of augmented reality (AR) technologies in industrial applications, which complements the understanding of how robotics and AR can enhance efficiency in logistics and warehousing. You can read more about this topic by visiting Augmented Reality in Industry. This piece provides insights into how AR and similar technologies are transforming traditional industries by optimizing operations, improving accuracy, and reducing costs, which are key aspects in the realm of logistics automation.

FAQs

What is Amazon Robotics?

Amazon Robotics is a subsidiary of Amazon that focuses on developing and implementing robotic technology for use in the company’s fulfillment centers and warehouses.

What are the main applications of Amazon Robotics?

Amazon Robotics is used for tasks such as warehouse automation, logistics, picking and packing, robot shipping, and palletizing.

How does Amazon Robotics improve efficiency in warehouses?

Amazon Robotics improves efficiency in warehouses by automating tasks such as picking, packing, and shipping, which reduces the time and labor required for these processes.

What are the benefits of using Amazon Robotics in warehouses?

The benefits of using Amazon Robotics in warehouses include increased speed and accuracy in fulfillment processes, reduced labor costs, and improved overall efficiency in warehouse operations.

How does Amazon Robotics impact the future of logistics and supply chain management?

Amazon Robotics is expected to have a significant impact on the future of logistics and supply chain management by enabling faster and more efficient order fulfillment, reducing errors, and optimizing warehouse space utilization.

Leave a Reply