In the realm of industrial automation, ABB Robotics stands as a beacon of innovation and efficiency. Founded in 1988, ABB has consistently pushed the boundaries of what is possible in robotics, integrating cutting-edge technology with practical applications across various sectors. The company has developed a diverse portfolio of robotic solutions that cater to a wide array of industries, including automotive, electronics, food and beverage, and pharmaceuticals.

With a commitment to enhancing productivity and safety, ABB Robotics has become synonymous with high-performance automation systems that not only streamline operations but also elevate the standards of quality and precision. The evolution of ABB Robotics is marked by its relentless pursuit of excellence and adaptability to changing market demands. As industries face increasing pressure to optimize production processes and reduce costs, ABB has responded by developing advanced robotic systems that leverage artificial intelligence, machine learning, and sophisticated sensor technologies.

These innovations enable robots to perform complex tasks with remarkable accuracy and speed, transforming traditional manufacturing paradigms into agile, responsive operations. As we delve deeper into the impact of ABB Robotics on manufacturing and quality control, it becomes evident that this company is not just a participant in the automation revolution; it is a leader shaping its future.

Key Takeaways

- ABB Robotics is a leading provider of industrial robots, modular manufacturing systems, and service.

- ABB Robotics has revolutionized manufacturing by increasing productivity, improving quality, and reducing costs.

- ABB Robotics plays a crucial role in quality control by ensuring precision, accuracy, and consistency in manufacturing processes.

- The advantages of ABB Robotics in manufacturing include increased efficiency, flexibility, and safety.

- ABB Robotics continues to innovate with advanced technologies such as collaborative robots and digital solutions, shaping the future of manufacturing.

The Impact of ABB Robotics on Manufacturing

Enhancing Human Capabilities

ABB’s robots are designed to work alongside human operators, enhancing their capabilities rather than replacing them. This collaborative approach fosters a more dynamic work environment where human intuition and robotic precision combine to achieve optimal results. The ability to automate repetitive tasks allows human workers to focus on more complex and creative aspects of production, ultimately leading to higher job satisfaction and productivity.

Driving Industry 4.0 Adoption

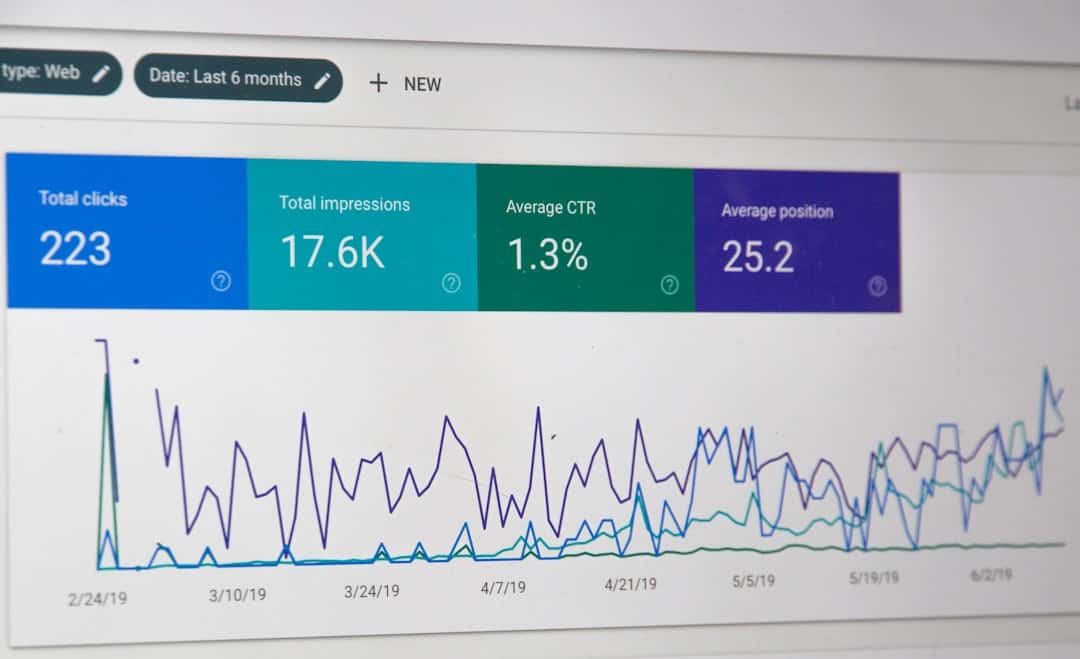

Moreover, ABB Robotics has played a pivotal role in driving the adoption of Industry 4.0 principles. The integration of IoT (Internet of Things) technologies with robotic systems enables real-time data collection and analysis, allowing manufacturers to monitor performance metrics and make informed decisions on the fly.

Unlocking the Power of Data-Driven Manufacturing

This data-driven approach not only enhances operational efficiency but also facilitates predictive maintenance, reducing downtime and extending the lifespan of machinery.

ABB Robotics in Quality Control

Quality control is a critical aspect of manufacturing that directly impacts product reliability and customer satisfaction. ABB Robotics has made significant strides in this area by developing advanced robotic solutions that ensure consistent quality throughout the production process. Utilizing high-resolution cameras and sophisticated vision systems, ABB robots can perform intricate inspections at speeds unattAInable by human workers.

These systems are capable of detecting defects, measuring dimensions, and verifying product specifications with unparalleled accuracy. The implementation of ABB Robotics in quality control not only enhances the precision of inspections but also accelerates the overall process. Traditional quality control methods often involve manual checks that can be time-consuming and prone to human error.

In contrast, robotic systems can operate continuously without fatigue, ensuring that every product meets stringent quality standards before it reaches the market. This level of automation not only reduces the risk of costly recalls but also builds consumer trust in the brand’s commitment to quality.

Advantages of ABB Robotics in Manufacturing

| Advantages | Description |

|---|---|

| Increased productivity | ABB Robotics can perform repetitive tasks with high speed and precision, leading to increased productivity in manufacturing processes. |

| Improved quality | The accuracy and consistency of ABB Robotics results in improved product quality and reduced defects in manufacturing. |

| Enhanced safety | Robots can handle hazardous tasks, reducing the risk of injury to human workers and improving overall safety in the manufacturing environment. |

| Flexibility | ABB Robotics can be easily reprogrammed and adapted to different tasks, providing flexibility in manufacturing processes. |

| Cost savings | By automating tasks, ABB Robotics can lead to cost savings in labor, energy, and materials, making manufacturing more efficient. |

The advantages of incorporating ABB Robotics into manufacturing processes are numerous and compelling. One of the most significant benefits is the increase in operational efficiency. Robots can work tirelessly around the clock, performing tasks with speed and precision that far exceed human capabilities.

This leads to shorter production cycles and higher output rates, allowing companies to meet growing consumer demands without compromising quality. Additionally, ABB Robotics contributes to enhanced workplace safety. By taking over hazardous tasks such as heavy lifting or working in extreme environments, robots minimize the risk of workplace injuries.

Furthermore, the integration of robotics can lead to a more ergonomic work environment for human operators, as they are relieved from repetitive strain tasks that can lead to long-term health issues.

ABB Robotics: Innovations and Technologies

ABB Robotics is at the forefront of technological innovation, continually developing new solutions that push the boundaries of what robots can achieve. One notable advancement is the integration of artificial intelligence (AI) into robotic systems. By leveraging machine learning algorithms, ABB robots can adapt to changing conditions on the production line, learning from their experiences to improve performance over time.

This adaptability is crucial in dynamic manufacturing environments where flexibility is key to success. Another significant innovation is the development of collaborative robots, or cobots, which are designed to work safely alongside human operators. These robots are equipped with advanced sensors that allow them to detect human presence and adjust their movements accordingly, ensuring a safe working environment.

This technology not only enhances productivity but also fosters a culture of collaboration between humans and machines, paving the way for a more integrated approach to manufacturing.

Case Studies: ABB Robotics Success Stories

The impact of ABB Robotics can be illustrated through various success stories across different industries. For instance, in the automotive sector, a leading manufacturer implemented ABB robots on its assembly line to automate the installation of components. The result was a 30% increase in production speed while maintaining impeccable quality standards.

By integrating robotic systems into their workflow, the manufacturer was able to respond more effectively to market demands and reduce lead times significantly. In another case study within the food processing industry, an organization faced challenges with packaging efficiency and consistency. By deploying ABB’s robotic solutions for packaging tasks, they achieved a remarkable reduction in labor costs while increasing throughput by 25%.

The robots were able to handle delicate products with care, ensuring that quality was never compromised during the packaging process. These success stories exemplify how ABB Robotics not only enhances operational efficiency but also drives innovation across various sectors.

Future of ABB Robotics in Manufacturing and Quality Control

Looking ahead, the future of ABB Robotics in manufacturing and quality control appears bright and full of potential. As industries continue to embrace automation and digital transformation, the demand for advanced robotic solutions will only grow. ABB is well-positioned to lead this charge with its ongoing commitment to research and development.

The integration of AI and machine learning will likely become even more sophisticated, enabling robots to perform increasingly complex tasks autonomously. Moreover, as sustainability becomes a focal point for manufacturers worldwide, ABB Robotics is poised to contribute significantly to greener practices. By optimizing energy consumption and reducing waste through precise automation, robotic systems can help companies meet their sustainability goals while maintaining profitability.

The future landscape will likely see an even greater emphasis on eco-friendly practices within manufacturing processes, with ABB leading the way through innovative robotic solutions.

ABB Robotics and the Future of Manufacturing

In conclusion, ABB Robotics has established itself as a leader in the field of industrial automation, significantly impacting manufacturing processes and quality control across various sectors. Through its innovative technologies and commitment to excellence, ABB has transformed traditional manufacturing paradigms into agile operations capable of meeting modern demands. The advantages offered by ABB Robotics—enhanced efficiency, improved safety, and superior quality control—are compelling reasons for manufacturers to adopt these solutions.

As we look toward the future, it is clear that ABB Robotics will continue to play a pivotal role in shaping the landscape of manufacturing. With advancements in AI, collaborative robotics, and sustainable practices on the horizon, the potential for growth and innovation remains vast. For computer enthusiasts and technology aficionados alike, following the developments within ABB Robotics offers a glimpse into the future of manufacturing—a future where human ingenuity and robotic precision work hand in hand to create unparalleled efficiencies and quality standards.

For those interested in the intersection of advanced robotics and emerging digital environments, exploring how technologies like those developed by ABB Robotics could integrate into new platforms such as the metaverse is fascinating. ABB Robotics focuses on industrial robotics, manufacturing automation, assembly, material handling, and quality control, all of which could see transformative applications in virtual spaces. A related article that delves into the challenges and opportunities of merging digital and physical realities, which is highly relevant to the application of robotics in such hybrid environments, can be found here: Metaverse and the Real World: Challenges of the Hybrid Reality. This article provides insights into how technologies like those from ABB might evolve and interact within these complex, layered realities.

FAQs

What is ABB Robotics?

ABB Robotics is a division of ABB Group, specializing in the development and manufacturing of industrial robots, robotic systems, and automation solutions for various industries.

What are the main applications of ABB Robotics?

ABB Robotics provides solutions for a wide range of applications including industrial robotics, manufacturing automation, assembly, material handling, and quality control in industries such as automotive, electronics, food and beverage, pharmaceuticals, and more.

What are the benefits of using ABB Robotics solutions?

The use of ABB Robotics solutions can lead to increased productivity, improved product quality, enhanced workplace safety, reduced production costs, and greater flexibility in manufacturing processes.

What types of robots does ABB Robotics offer?

ABB Robotics offers a diverse range of industrial robots including articulated robots, collaborative robots, SCARA robots, and delta robots, each designed for specific applications and industries.

How does ABB Robotics contribute to manufacturing automation?

ABB Robotics provides advanced automation solutions that help manufacturers streamline their production processes, increase efficiency, and adapt to changing market demands through the use of robotic systems and intelligent automation technologies.

What is the role of ABB Robotics in quality control?

ABB Robotics offers robotic solutions for quality control and inspection processes, including vision systems, measurement systems, and other technologies that help ensure product quality and consistency in manufacturing operations.

Leave a Reply